06-30-2025, 12:13 AM

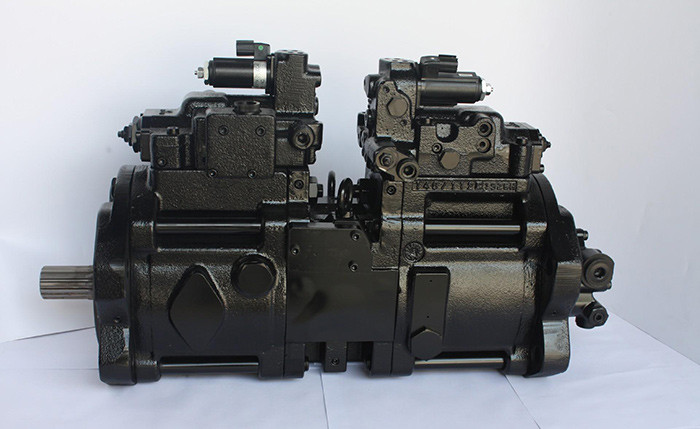

For an excavator, the hydraulic pump is the heart of its hydraulic system. When this vital component fails and needs to be replaced, it’s akin to a heart transplant in humans—an extensive and delicate procedure. Besides selecting the right hydraulic pump and a skilled technician, there are many post-replacement considerations. Just like human heart surgery, close monitoring after the procedure is essential.

1. Monitor the Operation of the New Pump for Three Months

After replacing the hydraulic pump, it's crucial to observe the machine during the break-in period. Pay attention to unusual vibrations, odd noises, or abnormal temperature changes in the oil. If any irregularities occur, diagnose the issue promptly to determine the underlying cause.

2. Avoid Load Immediately After Starting the New Pump

When starting the new hydraulic pump, avoid applying a load right away. Allow the machine to run without load for a period, especially in colder temperatures, to ensure sufficient warm-up time. Only gradually add load once the hydraulic circuit is confirmed to be circulating properly. During this time, carefully monitor the machine's performance.

3. Monitor Hydraulic Oil Temperature

After running the new pump for a period, observe the temperature changes in the hydraulic oil. Test the maximum and minimum oil temperatures under typical working conditions. By comparing the results over time, you can verify if the oil level is adequate and whether the hydraulic oil and cooling system are compatible.

4. Pay Attention to Noise from the Hydraulic Pump

Since the new hydraulic pump hasn’t undergone wear, it may produce unusual sounds if the hydraulic oil is dirty, lubrication is inadequate, or the load is too high. It’s important to detect such noise promptly and make necessary adjustments.

5. Observe the Machine's Movements

If the new hydraulic pump isn’t installed properly or the parameters don’t match, it may not be noticeable during idle operations. Therefore, when the machine starts actual work, pay extra attention to the smoothness of the excavator's movements and whether the power output is sufficient.

6. Adjust Hydraulic Valves After Replacement

Before the pump replacement, the owner or technician may have made adjustments to some hydraulic system valves. After installing the new pump, it’s essential to recalibrate the relevant valves to ensure they operate correctly and eliminate potential faults.

7. Regularly Check the Filter and Hydraulic Oil

After the pump replacement, regularly inspect the filters in the hydraulic circuit. Analyze the type and amount of contaminants on the filter screen to predict the source of potential failures. Additionally, check the hydraulic oil once a month to assess any degradation, discoloration, or contamination, which may indicate underlying issues.

Replacing a hydraulic pump is a significant task that requires careful attention both during and after the replacement. Proper monitoring and maintenance will ensure the excavator performs at its best and prevent any unforeseen issues from arising.

1. Monitor the Operation of the New Pump for Three Months

After replacing the hydraulic pump, it's crucial to observe the machine during the break-in period. Pay attention to unusual vibrations, odd noises, or abnormal temperature changes in the oil. If any irregularities occur, diagnose the issue promptly to determine the underlying cause.

2. Avoid Load Immediately After Starting the New Pump

When starting the new hydraulic pump, avoid applying a load right away. Allow the machine to run without load for a period, especially in colder temperatures, to ensure sufficient warm-up time. Only gradually add load once the hydraulic circuit is confirmed to be circulating properly. During this time, carefully monitor the machine's performance.

3. Monitor Hydraulic Oil Temperature

After running the new pump for a period, observe the temperature changes in the hydraulic oil. Test the maximum and minimum oil temperatures under typical working conditions. By comparing the results over time, you can verify if the oil level is adequate and whether the hydraulic oil and cooling system are compatible.

4. Pay Attention to Noise from the Hydraulic Pump

Since the new hydraulic pump hasn’t undergone wear, it may produce unusual sounds if the hydraulic oil is dirty, lubrication is inadequate, or the load is too high. It’s important to detect such noise promptly and make necessary adjustments.

5. Observe the Machine's Movements

If the new hydraulic pump isn’t installed properly or the parameters don’t match, it may not be noticeable during idle operations. Therefore, when the machine starts actual work, pay extra attention to the smoothness of the excavator's movements and whether the power output is sufficient.

6. Adjust Hydraulic Valves After Replacement

Before the pump replacement, the owner or technician may have made adjustments to some hydraulic system valves. After installing the new pump, it’s essential to recalibrate the relevant valves to ensure they operate correctly and eliminate potential faults.

7. Regularly Check the Filter and Hydraulic Oil

After the pump replacement, regularly inspect the filters in the hydraulic circuit. Analyze the type and amount of contaminants on the filter screen to predict the source of potential failures. Additionally, check the hydraulic oil once a month to assess any degradation, discoloration, or contamination, which may indicate underlying issues.

Replacing a hydraulic pump is a significant task that requires careful attention both during and after the replacement. Proper monitoring and maintenance will ensure the excavator performs at its best and prevent any unforeseen issues from arising.