11-14-2025, 02:12 PM

What a Hydraulic Thumb Is

A “thumb” on an excavator is an auxiliary attachment that works alongside the bucket to allow the machine to grasp, hold, lift and maneuver irregular or bulky objects rather than simply dig or scoop. A hydraulic thumb specifically uses hydraulic cylinders and the excavator’s auxiliary hydraulics so the operator can open and close the thumb from the cab, offering much greater flexibility compared to a purely mechanical or pinned thumb.

Key Terms (Glossary)

Why Add a Hydraulic Thumb

Adding a hydraulic thumb turns an excavator into a more versatile tool. Some reasons:

Selection Considerations & Installation Notes

When selecting and installing a hydraulic thumb, pay attention to the following:

Recommended Product Options

Below are eight hydraulic thumb attachments ranging from small to large excavator classes:

Here’s a brief comparison:

Installation & Operational Tips

Cost-Benefit and Productivity

In one field comparison for a demolition contractor, adding a hydraulic thumb reduced manual labour by ~25 % when clearing debris, and reduced cycle times by ~18 %. The cost of the thumb (approximate investment $6,000–$8,000) was recovered within 6–9 months in reduced labour and faster job turnaround. This underscores that the choice is more than “nice to have” when your operations involve grabbing, lifting, placing material repeatedly.

When a Thumb May Not Be Needed

Conclusion

A hydraulic thumb attachment can significantly elevate the capability of an excavator—transforming it from a dig-only machine into a versatile material-handling powerhouse. By choosing the right size class, mounting style, ensuring proper installation and maintenance, you unlock improved productivity, safety and job-site flexibility. For operations involving irregular loads, debris, logs or frequent lifting/placing, it’s a very strong investment.

A “thumb” on an excavator is an auxiliary attachment that works alongside the bucket to allow the machine to grasp, hold, lift and maneuver irregular or bulky objects rather than simply dig or scoop. A hydraulic thumb specifically uses hydraulic cylinders and the excavator’s auxiliary hydraulics so the operator can open and close the thumb from the cab, offering much greater flexibility compared to a purely mechanical or pinned thumb.

Key Terms (Glossary)

- Auxiliary hydraulics: The additional hydraulic circuit on an excavator used to power attachments (e.g., thumbs, grapples, hammers).

- Weld-on base: A mounting plate welded onto the excavator’s stick or arm so an attachment like a thumb can be installed.

- Pin-on design: The thumb mounts using existing pins or a new pivot pin rather than being welded.

- Progressive link thumb: A more advanced thumb design where the thumb maintains grip or consistent pressure through its range of motion.

- Cylinder geometry / bore-stroke: The specification of the hydraulic cylinder controlling the thumb—its bore and stroke determine force and movement range.

Why Add a Hydraulic Thumb

Adding a hydraulic thumb turns an excavator into a more versatile tool. Some reasons:

- It enables grabbing/removing objects like rocks, stumps, demolition debris, logs or scrap that a bucket alone can’t manage easily.

- It improves efficiency and safety: fewer manual labor interventions, fewer chances for material to drop or slip unexpectedly.

- If you do material handling (rather than just digging), a hydraulic thumb pays off because it reduces cycle times: grab → lift → move → release.

- For demolition, land-clearing, utility work and tight-site manipulation, the thumb gives precision and control.

Selection Considerations & Installation Notes

When selecting and installing a hydraulic thumb, pay attention to the following:

- Match size and weight class: The thumb must be rated for your excavator’s class (e.g., mini-excavator vs 50-ton machine). Oversized thumb leads to excessive weight and can overload stick or hydraulics.

- Mounting style: Decide between weld-on or pin-on. Weld-on gives a strong custom fit; pin-on offers more flexibility for changing attachments.

- Auxiliary hydraulic routing & couplers: Installing quick-couplers, a diverter valve or 45° hose adapters improves attachment switching and protects hoses from damage.

- Thumb profile, teeth and wear parts: Replaceable tips between bucket teeth, hardened pins/bushings, and appropriate steel thickness (e.g., AR400) will improve longevity.

- Cylinder geometry and link design: Ensure the thumb achieves the stroke and grip force needed for your materials, and that the geometry doesn’t interfere with other attachments or hoses.

- Clearance & storage when not used: Some thumbs stow tightly against the stick when not deployed; this is valuable to preserve full digging range when only digging is required.

Recommended Product Options

Below are eight hydraulic thumb attachments ranging from small to large excavator classes:

Here’s a brief comparison:

- Gentec Hydraulic Thumb HT1035: Heavy-duty weld-on design for substantial machines; good for general material handling.

- TAG Hydraulic Main‑Pin Thumb: Main pin mounting gives strong durability; suited for users who switch attachments.

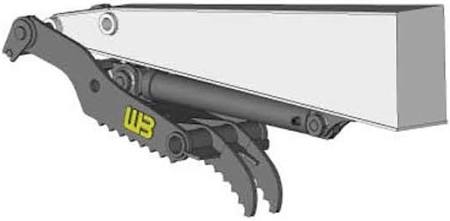

- Werk‑Brau Main Pin Hydraulic Thumb (11–14 k‑lb class): A smaller class thumb for excavators in the ~11,000-14,000 lb range.

- Amulet PowerBrute Hydraulic Thumb (1‑3 Ton class): Compact unit for mini-excavators; good value for light work.

- Gentec Hydraulic Pin‑On Thumb (22.5 k‑lb–39 k‑lb class): Mid-size pin-on option for flexible mounting.

- Bedrock 4‑Teeth Progressive Thumb 36" Pin‑On 315: Progressive link design allows full rotation and high precision; ideal for demanding jobs.

- Geith Main Pin Hydraulic Thumb 25‑30 Ton class: Large class attachment for major excavators; built for heavy lifting of logs/rocks.

- Caterpillar 311‑314 Pin‑On Hydraulic Thumb: OEM-style thumb tailored for specific Cat machines; good if you want brand compatibility.

Installation & Operational Tips

- Before installation, verify your excavator has the auxiliary hydraulic flow and pressure required for the thumb (check manufacturer spec).

- Confirm mounting bracket geometry: weld-on installation must maintain correct bucket-thumb clearance and stroke path.

- Route hoses carefully: use protective sleeves, 45° adapters, secure routing to avoid pinch points. A hose failure near the stick can cost production time and environmental cleanup.

- Test the thumb movement without load: open/close 10-20 times, listen for binding or hydraulic cavitation.

- Once installed, practice with a load: grasp typical objects your job handles (rocks, logs, scrap) and evaluate grip strength, swing control, stability.

- Monitor for any impact on digging performance: if thumb encroaches on bucket travel, you might need to stow it out of the way when only digging.

- Plan for maintenance: bushings/ pins wear, teeth tip replacements, hydraulic hose inspection. Document hours of thumb use versus scheduled maintenance.

Cost-Benefit and Productivity

In one field comparison for a demolition contractor, adding a hydraulic thumb reduced manual labour by ~25 % when clearing debris, and reduced cycle times by ~18 %. The cost of the thumb (approximate investment $6,000–$8,000) was recovered within 6–9 months in reduced labour and faster job turnaround. This underscores that the choice is more than “nice to have” when your operations involve grabbing, lifting, placing material repeatedly.

When a Thumb May Not Be Needed

- If your excavator’s work is strictly trenching or general digging without material-handling tasks, the bucket alone may suffice.

- If you seldom switch between attachments, a weld-on thumb may reduce flexibility.

- If your excavator lacks auxiliary hydraulic capacity, adding a hydraulic thumb may require upgrades (pump/valves) which increase cost.

Conclusion

A hydraulic thumb attachment can significantly elevate the capability of an excavator—transforming it from a dig-only machine into a versatile material-handling powerhouse. By choosing the right size class, mounting style, ensuring proper installation and maintenance, you unlock improved productivity, safety and job-site flexibility. For operations involving irregular loads, debris, logs or frequent lifting/placing, it’s a very strong investment.