| Welcome, Guest |

You have to register before you can post on our site.

|

| Online Users |

There are currently 141 online users.

» 1 Member(s) | 130 Guest(s)

Amazon, Bing, Claude, DotBot, Facebook, Google, OpenAI, Petalbot, Semrush, Seznam, MikePhua

|

| Latest Threads |

2017 Sumitomo SH200-6 Exc...

Forum: Used Excavators For Sale

Last Post: MikePhua

Yesterday, 09:23 PM

» Replies: 0

» Views: 2

|

2021 LiuGong CLG920E Exca...

Forum: Used Excavators For Sale

Last Post: MikePhua

Yesterday, 08:51 PM

» Replies: 0

» Views: 1

|

2010 Hitachi ZX200-3 Exca...

Forum: Used Excavators For Sale

Last Post: MikePhua

Yesterday, 08:47 PM

» Replies: 0

» Views: 1

|

Why Do Used Construction ...

Forum: Used Excavators For Sale

Last Post: MikePhua

Yesterday, 06:48 PM

» Replies: 0

» Views: 7

|

2018 Kobelco SK350LC-10 E...

Forum: Used Excavators For Sale

Last Post: MikePhua

Yesterday, 05:09 PM

» Replies: 0

» Views: 3

|

2017 Komatsu PC56-7 Excav...

Forum: Used Excavators For Sale

Last Post: MikePhua

Yesterday, 05:02 PM

» Replies: 0

» Views: 3

|

2020 SANY SY365H Pro Exca...

Forum: Used Excavators For Sale

Last Post: MikePhua

Yesterday, 04:55 PM

» Replies: 0

» Views: 1

|

2020 Hitachi ZX240-5A Exc...

Forum: Used Excavators For Sale

Last Post: MikePhua

Yesterday, 04:49 PM

» Replies: 0

» Views: 1

|

1990 Caterpillar D8R Bull...

Forum: Used Excavators For Sale

Last Post: MikePhua

Yesterday, 04:42 PM

» Replies: 0

» Views: 2

|

2011 Sumitomo SH210-5 Exc...

Forum: Used Excavators For Sale

Last Post: MikePhua

Yesterday, 04:36 PM

» Replies: 0

» Views: 1

|

|

|

| Doosan DH55GOLD Excavator Review: A User's Experience |

|

Posted by: MikePhua - 06-28-2025, 05:10 PM - Forum: Operator Talking

- No Replies

|

|

In this interview, we explore the experience of a Doosan DH55GOLD excavator owner from Shandong, China, a member known as "boshan55." He became a member in October 2009 while studying in South Korea. Growing up with a keen interest in excavators due to his family's influence, he returned to China in 2010 and chose to start his own excavation rental business. His family previously owned a Komatsu PC55MR, and after returning, he decided to invest in a Doosan DH55GOLD. As a 1980s generation excavator owner with overseas study experience, boshan55’s story offers valuable insights into the excavation rental industry.

Purchase Details: - Purchase Date: April 2025

- Price: 350,000 RMB (with a 20% down payment, financed over 3 years)

- Working Hours: 620 hours

- Reason for Choice: Before purchasing the Doosan DH55GOLD, boshan55 considered an 8-ton Kubota KX185. However, due to limited funds and the small size of the KX155 (a tail swing machine), he opted for the 5-ton Doosan DH55GOLD. He chose Doosan for its affordable price, low maintenance costs, and availability of reasonably priced parts.

Despite the initial excitement about the purchase, boshan55 faced some disappointments during the transaction. He encountered discrepancies in the price quoted by the dealer before signing the contract, which ended up including an unexpected 8,000 RMB guarantee fee that was never mentioned. He also received a promise for a free hydraulic hammer and a washing machine, which were never delivered. Furthermore, the delivery date was delayed by half a month, which also caused frustration as the dealer failed to pay the promised penalty for the delay.

Work Conditions:- Primary Tasks: The Doosan DH55GOLD is primarily used for small-scale site jobs, including foundation work, leveling, and clearing debris. Occasionally, it is used for road repairs and agricultural water conservancy projects.

Work Efficiency:- Speed: The Doosan DH55GOLD has a relatively fast swing speed, but its arm and bucket movements are slow, leading to a perceived lack of efficiency. On some occasions, supervisors on the worksite mistakenly believed the machine was deliberately delaying work. Boshan55 laughs about it, saying, "The machine just can’t move faster; that’s its design." Comparing it to his Komatsu PC55-MR, the difference in speed is quite noticeable.

Fuel Consumption:- Fuel Usage: The fuel consumption is approximately 4.5 liters per hour under full load, meaning that a 500 RMB fuel cost lasts for about two days of work.

Product Performance and Issues:- Engine: As a new machine, the engine has not had significant problems, except for an incident where the shutdown pull-cord fell off, which was quickly resolved.

- Hydraulic System: No major issues have occurred with the hydraulic system thus far.

- Other Problems: There have been issues with greasing the arm and bucket joints, where the grease gun couldn’t inject grease. Despite reporting the issue, it took a week for the dealer to respond. After five hours of attempted repairs, the dealer was unable to resolve the issue and even damaged a grease gun. The part required for the repair was unavailable, and as of now, the problem remains unresolved.

Dealer and After-Sales Service:- Dealer Experience: Boshan55 has been disappointed with the dealer, Shandong Yonghong Engineering Machinery Co., Ltd. From broken promises during the purchase process to subpar after-sales service, his experience with Doosan’s dealer has left him disillusioned. He compares the service unfavorably with the other brands he owns, citing the slow response to issues and lack of professionalism.

Parts:- Parts Availability: Boshan55 mentions that Doosan parts are reasonably priced compared to other brands, which was a key factor in his decision to purchase this model. However, the overall experience with parts has not been entirely smooth.

Overall Evaluation:

Despite Doosan’s high market share in China, boshan55’s experience has been mixed. Initially, he had a favorable impression of Doosan, but his dealings with the dealer have left him feeling frustrated. He points out that, if the situation isn’t resolved, he wouldn’t consider purchasing Doosan machines again and would advise his friends and family against doing so. In an industry where user reputation is crucial, the rise of domestic brands with better customer service has challenged Korean manufacturers like Doosan. Boshan55’s experience highlights the importance of maintaining good communication and reliable service to keep customer loyalty intact.

It’s hoped that Doosan and its dealers can address these issues and improve customer satisfaction, ensuring the brand remains a strong contender in the Chinese market’s excavator segment.

|

|

|

| Doosan DH220LC-7 Excavator Review: Insights from an Experienced User |

|

Posted by: MikePhua - 06-28-2025, 05:09 PM - Forum: Operator Talking

- No Replies

|

|

Doosan is a well-established brand in the Chinese market, with the DH220LC-7 being one of their top-selling models. Today, we interview a seasoned excavator user, Wang Zipan (referred to as “Mr. Wang”), a former military officer turned business owner who now runs a large fleet of construction machinery. In addition to operating dozens of excavators, Mr. Wang is also the exclusive regional distributor for a certain brand of breaker hammers. His journey in the excavator business offers valuable insights for users across the industry.

Purchase Details - Purchase Date: September 20, 2006

- Payment Method: Installments

- Purchase Price: 780,000 RMB, with a 20% down payment and the balance paid in two years

- Reason for Purchase: When choosing an excavator, Mr. Wang considered three brands: Caterpillar, Volvo, and Doosan. Ultimately, he selected Doosan due to its competitive pricing, which offered a faster return on investment and lower risk for a first-time purchase. Over time, he also purchased other models such as the Doosan DH225LC-7, Caterpillar 320D, and Komatsu PC220-8.

Work Conditions- Primary Work: The Doosan DH220LC-7 is primarily used for earthwork and rockwork. Mr. Wang’s machine is frequently employed in road construction and local aluminum mining for rockwork.

Work Efficiency- According to Mr. Wang, the Doosan DH220LC-7 operates relatively slowly compared to other machines on the same site, especially when compared to Caterpillar and Komatsu machines. However, overall, its work efficiency is still adequate for most projects.

Fuel Consumption- Since most of the work is contracted out to the site, with the site covering fuel costs, the Doosan DH220LC-7 has demonstrated good fuel efficiency. Under full load, it consumes 17-18 liters per hour, which is approximately 5-6 liters less than his Komatsu PC220-8, indicating solid fuel economy.

Performance Issues- Engine: To date, the engine has not experienced any major issues and performs reliably.

- Hydraulic System: After 800 operating hours, the hydraulic system showed some oil leakage at the main pump and distributor valve, but it did not affect the machine’s operation.

After-Sales Service- Doosan’s authorized dealer in Henan is Qianlima Engineering Machinery Co., Ltd., one of China’s largest equipment dealers. Mr. Wang comments that their after-sales service is generally good, with timely responses thanks to the dealer’s broad coverage. Despite this, most of the maintenance work is done in-house, reflecting the growing scale and professional development of Mr. Wang’s rental business.

Parts Procurement- Mr. Wang shared that, with extensive knowledge about his equipment, he no longer relies on the dealer for parts after the warranty expires. Instead, he directly sources parts from subcontracted manufacturers, as many parts are not produced by the original manufacturers but outsourced to third parties. By doing so, Mr. Wang saves a significant amount on parts costs. His strong in-house repair capabilities and deep understanding of the equipment allow him to avoid the high prices set by manufacturers and dealers, which is a lesson worth learning for other users.

Overall Assessment- Overall, the Doosan DH220LC-7 is a reliable and stable machine, well-suited for earth and rockwork, especially for those entering the excavator market. While its work speed may not be the fastest, it offers excellent fuel economy, performance stability, and good after-sales service. For new users or small-to-medium businesses, the DH220LC-7 is an excellent option.

Mr. Wang’s experiences provide valuable lessons for excavator users, particularly regarding parts procurement and maintenance practices. His approach to cost-saving and equipment management is a model that many other operators can learn from.

|

|

|

| User Review of Komatsu PC200-8 Excavator After 6,000+ Operating Hours |

|

Posted by: MikePhua - 06-28-2025, 05:07 PM - Forum: Operator Talking

- No Replies

|

|

This review focuses on the Komatsu PC200-8 excavator, a machine used by the owner "Komatsu-8" from Tangshan, Hebei, who also operates two other machines: a Caterpillar 345D and a Caterpillar 320C. After using the PC200-8 for over 6,000 hours, the user shares valuable insights into the excavator's performance, fuel consumption, and maintenance issues.

Purchase Details: - Purchase Date: January 2008

- Dealer: Hebei Shijiazhuang Tianyuan, an authorized Komatsu dealer

- Purchase Price: ¥985,000 (full payment)

- Current Operating Hours: 6,080 hours

- Common Applications: Mainly used for earthmoving tasks such as roadwork and foundation digging, with rare encounters in rock excavation.

Work Efficiency:- The PC200-8 has proven efficient for tasks like loading soft soil. The user reports that it can load a 23 cubic meter truck in 3-4 minutes, with the exception of some models by Sumitomo, which are slightly faster. Overall, this Komatsu excavator performs well in terms of speed on-site.

Fuel Consumption:- Full Load (A mode): 19 liters per hour

- Economy Mode (E mode): 17 liters per hour

- The excavator uses a fuel-injected engine, which is sensitive to fuel quality.

Performance Issues and Maintenance:- Engine Issues:

- At 3,681 operating hours, three of the injector nozzles failed due to poor fuel quality, costing ¥5,690 per nozzle to replace. The user had to use the dealer’s service center because of the urgency, although the price felt high.

- Hydraulic System:

- The hydraulic cylinders, including the boom and bucket cylinders, have become severely discolored (turned black), although the hydraulic oil has been changed at 4,950 hours as per the service provider’s recommendation. Despite the discoloration, the oil temperature remains normal, and the user has not noticed any leaks or performance issues.

- The user continues to work with the dealer to address the issue of the blackened cylinders, though the dealer has not provided a satisfactory explanation.

Dealer Service:- The user appreciates the timely service from Komatsu's Hebei dealer, Shijiazhuang Tianyuan. The company provides fast response times, often resolving issues within an hour of the user's call, thanks to the proximity of the dealership.

Parts and Pricing:- Parts Pricing:

- One significant drawback is the cost of replacement parts, especially for the fuel-injection system. The user finds the price of replacement parts to be unreasonably high, particularly because of the fuel-injected engine.

- Injector Nozzles:

- As mentioned, the injector nozzles cost ¥5,690 each, which the user feels reflects high dealer profits.

Overall Evaluation:- Performance: The Komatsu PC200-8 is efficient and delivers high productivity on the job site. The user is generally satisfied with its performance, citing good working speed and reliable dealer service.

- Areas for Improvement: The fuel consumption is higher than expected, and parts costs—especially for fuel injectors—are considered excessively high. The user hopes Komatsu and its dealers can better consider customer concerns about pricing and make adjustments accordingly.

Overall, despite some drawbacks, the Komatsu PC200-8 has proven to be a reliable machine with solid performance for various construction tasks.

|

|

|

| Komatsu's Upgraded Crawler Transporter: The CD60R-3 |

|

Posted by: MikePhua - 06-28-2025, 04:40 PM - Forum: Equipment Market News

- No Replies

|

|

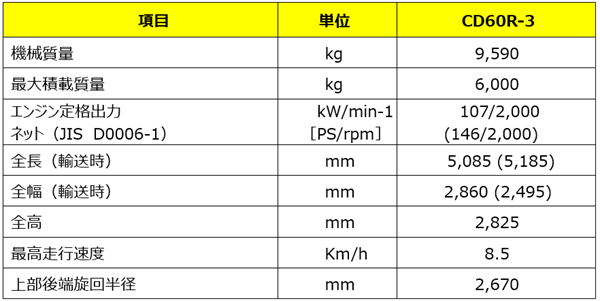

Komatsu has recently unveiled an upgraded version of its 6-ton full rotation crawler transporter (also known as the 360-degree rotating crawler transporter), which will be sold as the "CD60R-3" starting from June 2025. The product was showcased at the Japan International Construction Machinery and Surveying Expo (CSPI-EXPO) held from June 18 to 21.

Product Overview:

Komatsu first launched the full rotation crawler transporter, CD60R-1, in 1996. The model quickly became popular for tasks like land leveling, farmland reclamation, forestry road construction, and river engineering, especially in non-paved terrains. Its durability, 360-degree rotation functionality, and compact design, which allows operation in tight spaces, have made it highly favored by users. Over the years, the demand for the CD60R-1 has also grown in post-disaster reconstruction projects.

The CD60R-3 features a new and upgraded engine, offering higher output power and improved fuel efficiency. This enhances both the economic performance and environmental sustainability of the machine. Additionally, the redesigned engine layout has significantly improved the driver’s visibility on the right side of the vehicle. New features like surrounding surveillance cameras, digital tilt angle displays, and maintenance-free batteries have also been added to boost safety and convenience, meeting customer needs more precisely.

Key Features:

1. Environmental and Economic Efficiency: - New Engine Power Boost: The new engine delivers an 8% increase in power while reducing fuel consumption. It is equipped with the SAA4D107E-5 engine, meeting the non-road mobile machinery emissions standards.

- Automatic Power Reduction: The machine is equipped with automatic power reduction and idling stop features, which lower the engine RPM or stop the engine during idle times, minimizing unnecessary fuel consumption.

2. Safety and Reliability:- Improved Visibility: The engine layout has been redesigned to improve the driver’s visibility, enhancing safety during operation. The CD60R-3 comes standard with rear and right-side surveillance cameras, eliminating blind spots.

- Digital Tilt Angle Display & Warning Alerts: A built-in Inertial Measurement Unit (IMU) provides real-time digital tilt angle readings. If the machine tilts too far, the display will change color and an alarm will sound. The machine also features a warning when the bucket is raised but not lowered, reducing the risk of operational negligence.

3. Durability and Maintenance:- Overload Warning System: The machine is equipped with an overload warning light that displays the load status in real time, preventing potential safety hazards and damage caused by overloading.

- Maintenance-Free Battery: The CD60R-3 is equipped with a maintenance-free battery that doesn’t require electrolyte checking, and an indicator light clearly shows its status. Additionally, the optimized battery compartment design makes it easier to maintain the vehicle.

4. Transport Efficiency:- Lightweight Compact Design: With an overall weight of less than 10 tons, the lightweight design offers flexibility in transport options. It also performs exceptionally well in narrow spaces, providing excellent maneuverability and adaptability on-site.

Conclusion:

The new Komatsu CD60R-3 crawler transporter continues to embody the company’s commitment to innovation in construction machinery. With its enhanced safety, improved efficiency, and durable design, this machine is set to meet the demanding needs of modern construction projects, especially in challenging and confined environments.

|

|

|

| Zoomlion’s Giant Crane Supports 2030 World Cup Stadium Construction |

|

Posted by: MikePhua - 06-28-2025, 04:34 PM - Forum: Equipment Market News

- No Replies

|

|

Under the scorching sun of Morocco, the giant arm of the Zoomlion ZCC9800W crawler crane slowly moves, precisely lifting hundreds of tons of steel structures into place, contributing to the construction of the Rabat Sports Stadium for the 2030 FIFA World Cup. This stadium will welcome global football fans during the upcoming tournament.

As the 2030 World Cup draws closer, host country Morocco is accelerating its stadium construction efforts. The Zoomlion ZCC9800W crawler crane, a "giant" and "star product" in the construction machinery field, is playing a central role in the project, showcasing exceptional lifting capabilities on Moroccan construction sites. The equipment has received high praise from the project team: "Its overall lifting performance far surpasses other products in the same category."

The construction of the stadium involves lifting numerous heavy-duty equipment and components into precise locations. With its powerful lifting capacity and stability, Zoomlion's equipment handles these challenging tasks with ease. After completing the major lifting tasks at the Rabat Sports Stadium, this "Made-in-China" crane, weighing in at over 1,000 tons, will move on to assist in the construction of the world’s largest football stadium, the Hassan II Stadium.

The ZCC9800W is not only active in sports stadium construction but has also made its mark in wind turbine and petrochemical lifting projects. The crane has proven its resilience in extreme environments, operating stably in the frigid -40°C temperatures of Inner Mongolia and lifting with precision even in wind speeds exceeding 8m/s in Vietnam. Furthermore, the ZCC9800W was the first of its kind to enter the European market, proving that Chinese manufacturing has a strong voice in the high-end equipment sector.

In recent years, Zoomlion has continued to make strides in the large-tonnage crane sector, producing world-class crawler cranes and all-terrain cranes that have been highly successful globally. These products redefine "high-end equipment" with their extraordinary technical strength, setting new benchmarks for large-tonnage cranes worldwide. Zoomlion's growth reflects the rise of China’s high-end manufacturing in the global construction machinery industry.

|

|

|

| Sumitomo SH210A5 Excavator: User Report |

|

Posted by: MikePhua - 06-28-2025, 04:25 PM - Forum: Operator Talking

- No Replies

|

|

This report focuses on the experiences of a user who works as a project supervisor. After graduating from university, he developed a strong interest in excavators commonly used on construction sites. In 2008, he bought a second-hand Hitachi ZX225US zero-tail excavator. Due to frequent minor issues, he eventually sold it for 280,000 RMB. In 2010, he purchased a brand-new Sumitomo SH210A5 excavator and began his journey in the excavator rental industry. Let's take a closer look at the usage details of his SH210A5 excavator.

Purchase Information

When purchasing the excavator, the user considered three different models: the Kato HD820-R (his first choice), the Kobelco SK200 Super 8, and the Sumitomo SH210A5. Although the Kato HD820-R was his preferred option, it was ultimately dismissed due to high down payment requirements and unfavorable financing terms. The Kobelco SK200 Super 8 was also ruled out because of concerns over the quality of its domestically produced engine and hydraulic components. The Sumitomo SH210A5, on the other hand, was appealing due to its fully imported core components from Japan and flexible financing options, which led to its final selection. - Down Payment: 270,000 RMB

- Loan Amount: 60,000 RMB (to be paid off in one year)

- Total Price: 1,090,000 RMB

Working Conditions

Since purchasing the excavator, it has primarily been used for bulk earthworks and stoneworks, with work charged on a daily basis. The user mentioned that the SH210A5 performs exceptionally well when doing earthworks, with fast speed and sufficient power. However, when working on stoneworks, the user noticed some wobbling at the junction of the boom and arm, which made the machine feel less solid compared to a similar-sized Caterpillar model on the same site. He suspected this could be due to differences in the steel quality.

Work Efficiency

The Sumitomo SH210A5 demonstrates high efficiency in daily operations. Whether loading trucks or digging, it performs the fastest on the construction site. The user stated, "None of the same models on the site can outperform my Sumitomo 210," confirming the machine’s speed advantage.

Fuel Consumption

The fuel consumption for the SH210A5 is relatively low compared to other similar models. The excavator has three different working modes:- A Mode: Light mode with lower fuel consumption.

- H Mode: Speed mode, used for faster operations.

- SP Mode: A combination of speed and power.

In A Mode, the fuel cost is approximately 100 RMB/hour when running the air conditioner. The user noted that speed is very fast in this mode, but they were advised by the operator not to use H Mode too much as it runs too fast, and SP Mode is rarely used. The fuel consumption in A Mode provides an excellent balance of efficiency and power.

Performance and Issues- Engine: No faults or issues have occurred with the engine since purchase.

- Hydraulic System: The hydraulic system has not experienced any significant issues.

- Chassis: No faults have been observed with the chassis.

- Cab: The cab is luxurious and equipped with a large window for excellent visibility. It also has a small bench behind the seat for apprentices, with hooks for hanging clothes and a small refrigerator. The design is very user-friendly. However, the suspension and sealing of the cab are not as good, which makes the operator feel significant jolts when doing stonework. The seat’s comfort is not as good as that of Hitachi or Caterpillar machines. Additionally, the sound system is not loud enough, which can be a problem for the operator who enjoys listening to music while working.

After-Sales Service

The Sumitomo SH210A5’s after-sales service is provided by Jiangxi Zhongrui Engineering Machinery Co., Ltd. The user is quite satisfied with the dealer's customer service. Once, when the walking alarm light was not functioning, the after-sales staff arrived at the construction site at 10 PM, even though the issue turned out to be a misunderstanding (the operator didn’t want to work late). Despite the false alarm, the dealer’s willingness to respond so promptly left a positive impression.

Summary

Thanks to its flexible purchase policy, fully imported core components, and good fuel economy, the Sumitomo SH210A5 was a solid choice for the user. Since its purchase, the excavator has shown reliable performance, excellent efficiency, and a low failure rate. Although there are some minor issues, such as the cab's comfort and the sound system, the overall performance has been impressive. The user plans to continue monitoring the machine's performance, and we will keep you updated with any further feedback.

|

|

|

| Kubota KX161 Excavator User Review |

|

Posted by: MikePhua - 06-28-2025, 03:18 PM - Forum: Operator Talking

- No Replies

|

|

Kubota is a globally recognized manufacturer of mini excavators, with a market share consistently ranking first in the world. In China, Kubota offers several models, including the U15, KX135, KX155, KX161, and KX185. This review focuses on the KX161, a 6-ton model that has gained popularity among excavator operators. The user featured in this review is "Wei Wei," an experienced excavator owner and operator, who shares his experience with the KX161 after years of use.

Purchasing Information

Wei Wei purchased his Kubota KX161 excavator in March 2008 from Kubota’s Hubei agent, Wuhan Hongji. The total price at the time was 440,000 RMB, with a down payment of 100,000 RMB and the remainder to be paid over three years. After more than 3,400 operating hours, Wei Wei continues to use the excavator effectively.

Operational Conditions

Wei Wei uses the KX161 mainly on construction sites and agricultural land improvements. The excavator is often used for river dredging and other related tasks, which require its versatility and durability.

Operator Experience

Wei Wei operates the KX161 himself. He learned various excavator skills, including digging, dredging, and grading, under the guidance of a more experienced operator. Within two months of starting, he was already dredging rivers, gaining proficiency quickly. Now, he even mentors apprentices, passing on his knowledge to the next generation.

Fuel Consumption

Wei Wei reports that with a full 70-liter tank, the excavator can operate for approximately 10 hours, resulting in a fuel consumption rate of about 7 liters per hour. He considers this fuel consumption to be quite efficient compared to other machines he works with.

Work Efficiency

The KX161 is known for its quick and stable work performance. Although the digging power is average, Wei Wei finds that the machine works efficiently for most tasks. Its speed and stability are crucial for completing various jobs quickly.

Machine Performance and Issues

The KX161 has proven to be highly reliable, with few issues reported during its operation. Below are some key performance notes:

- Engine: The engine has been trouble-free since purchase, with zero issues.

- Hydraulic System: No major problems have occurred in the hydraulic system, though there was a minor oil leak in one of the hydraulic pipes. After an inspection by the dealer, it was determined that the issue didn’t affect performance, so no repairs were made.

- Undercarriage: At 2,000 and 3,100 hours, the two counterweight rollers and track rollers were replaced at a 10% discount by the dealer. Since then, no further issues have been reported.

Key Advantages and Disadvantages

Wei Wei highlights several features of the KX161 that contribute to its effectiveness in various tasks, especially in conditions where other machines might struggle:

- Zero Tail Swing: The KX161’s zero tail swing feature makes it ideal for working in tight spaces. Unlike machines with tails, the KX161 can operate without the risk of damaging surrounding structures or obstacles.

- Wide 600mm Tracks: Unlike many 6-ton excavators that use 450mm tracks, the KX161 features 600mm tracks, a design typically found in 20-ton excavators. This gives Wei Wei better stability, particularly for tasks like riverbed dredging and pond excavation, where narrow tracks could easily get stuck. Wei Wei also added custom "pads" under the tracks to prevent the machine from sinking.

- Anti-theft Key System: The KX161 is equipped with a unique anti-theft key system. Each key is coded with a chip that matches the excavator, making it impossible to start the machine with any other key. If someone tries, the machine will alarm, making theft much more difficult.

- Boom Swing Feature: Although the KX161 includes a boom swing feature, Wei Wei rarely uses it. He feels it’s unnecessary for most tasks and that it can lead to wear on the boom over time.

- Cab Space and Audio System: The cab is a bit cramped for someone of Wei Wei’s height (1.8 meters). He notes that the limited space can be uncomfortable during long working hours. Additionally, the sound system lacks deep bass, which is something Wei Wei enjoys while working. To address this, he installed a subwoofer to enhance his listening experience.

After-Sales Service

Wei Wei is generally satisfied with the after-sales service from Kubota’s Hubei agent, Wuhan Hongji, especially during the warranty period. However, after the warranty expired, he noticed a slower response time when issues arose. “It sometimes takes a few days for them to come, which is a bit disappointing compared to before,” he remarked.

Parts and Maintenance

Parts are typically sourced from the agent’s service team or ordered from nearby service centers. Wei Wei finds the availability of parts convenient due to the proximity of the service center. He also mentions that the prices for parts are reasonable.

Conclusion

As one of the best-selling mini excavators globally, Kubota’s KX161 has earned a solid reputation for reliability and performance. Wei Wei’s experience supports this, highlighting the machine’s excellent fuel efficiency, innovative features like zero tail swing, and sturdy design. While the machine has had a few minor issues, these have been promptly addressed by the dealer. Wei Wei is satisfied with his KX161 and continues to rely on it for various excavation tasks. However, he hopes that after-sales service could improve post-warranty to maintain high levels of customer satisfaction.

|

|

|

| Lonking LG6060 Excavator Usage Report |

|

Posted by: MikePhua - 06-28-2025, 03:03 PM - Forum: Operator Talking

- No Replies

|

|

Li Ning, a post-80s excavator operator, started his career in excavating machinery after his family purchased their first excavator, the Lonking LG6060, in 2008. His father, with years of experience handling bulldozers, influenced Li Ning’s passion for machinery. From self-learning the operation and maintenance of excavators, Li Ning has since become an experienced operator, often sharing his expertise and lessons learned. Here, he shares his experience with the Lonking LG6060 after years of use.

Purchasing Information

Li Ning purchased his Lonking LG6060 excavator in the second half of 2008 from Lonking’s Henan agent, Shengshi Xing, via installment payments. He made an initial payment of 160,000 RMB and has been paying off the remainder over two years. Li Ning has high regard for the service from Shengshi Xing, particularly their flexible payment options. He appreciates their understanding, especially when business is slow: “When work was light, they allowed us to pay a bit later without pressuring us. Which other dealers would do that?”

Operational Conditions

Li Ning’s excavator is primarily used on construction sites and for agricultural land transformation. The main tasks include digging drainage ditches, leveling sites, and loading materials. The LG6060 proves itself to be a versatile and reliable machine for these daily operations.

Work Efficiency

Li Ning notes that the work efficiency of the LG6060 is decent, though its movements are somewhat slow. While it gets the job done, Li Ning feels that its slower pace is a downside, especially when compared to other models. However, considering the balance between cost and performance, the LG6060 still meets most of his needs.

Machine Performance and Issues

Since the purchase, the LG6060 has generally performed well, with only minor issues. Below are some specific issues and their resolutions:

- Engine: There have been no issues with the engine, and it has run without any major problems.

- Hydraulic System: Although no significant failures occurred, Li Ning experienced an issue with a multi-way valve oil pipe that leaked. The agent replaced the pipe free of charge, and the problem was resolved.

- Oil Level Sensor: There was a problem with the oil level sensor not displaying correctly. The agent replaced it under warranty, and the issue was resolved.

- Air Conditioning: The air conditioning had poor cooling performance, but after the agent added Freon free of charge, the cooling improved significantly.

Fuel Consumption

Li Ning generally operates the machine at 1800 RPM, consuming approximately 28 RMB per hour (about 4.5 liters per hour). For hourly jobs, he uses a larger throttle, while for contracted work, the throttle is smaller. Li Ning considers this fuel consumption to be average for excavators of similar size—not too fuel-efficient, but not wasteful either.

After-Sales Service

Li Ning is generally satisfied with the after-sales service for the Lonking LG6060. Issues are quickly addressed, and he appreciates the responsive customer support from the dealer, Shengshi Xing. However, he notes that after the warranty period, service responsiveness seemed to decrease. "It might be due to a lack of sufficient after-sales staff," he speculates. Despite this, Li Ning is still satisfied with the overall service, and he plans to purchase a larger excavator from Lonking later this year.

Suggestions

When asked for feedback about Lonking and its dealers, Li Ning commended Shengshi Xing for their excellent service during the warranty period. However, he suggested that after the warranty ends, service could become more timely to maintain the same high level of customer satisfaction. For the construction machinery industry, user reputation is critical, and providing excellent after-sales service is essential for maintaining a strong customer base.

Conclusion

Overall, Li Ning is satisfied with his Lonking LG6060, a 6-ton excavator from a domestic brand. While there have been some minor issues, they were resolved promptly with minimal downtime. The machine offers a good balance of performance and cost, and Li Ning remains positive about Lonking’s future products. However, he hopes that the dealer can improve after-sales service post-warranty to ensure continued customer satisfaction and loyalty in the competitive machinery market.

|

|

|

| Komatsu PC200-8 6000-Hour Usage Report |

|

Posted by: MikePhua - 06-28-2025, 02:59 PM - Forum: Operator Talking

- No Replies

|

|

I have been using the Komatsu PC200-8 for three years, and I recently completed the 6000-hour service. Here's a brief summary of my experience over the past three years.

Purchase and Initial Use

I purchased this Komatsu PC200-8 directly from the dealer, and I have been the sole operator and maintainer of the machine since day one. Initially, everything ran smoothly without any issues. The main goal was to own a machine that is reliable and easy to maintain.

Faults and Repairs

The biggest issue I encountered occurred around 3681 hours, when three out of six fuel injectors burned out. After checking, it turned out the problem was due to poor-quality fuel. I had to replace all the injectors, which cost 5960 yuan each. Though this repair was expensive, I opted to go with the service station to get the machine back to work quickly. Although the repair cost was high, I had no other choice but to replace the injectors.

Current Condition and Maintenance

Currently, the second arm cylinder and bucket cylinder have become severely discolored (blackened). Despite contacting the dealer's after-sales service multiple times, I still have not received a clear response. The hydraulic oil temperature remains normal, and there has been no impact or damage to the machine. I replaced the hydraulic oil at 4950 hours, and the service station said it should be changed every 5000 hours. I also ensure that the filter elements are replaced at the appropriate intervals, as well as the three filters. All of these are original parts from the manufacturer.

Maintenance and Service

Aside from the issues with the cylinders, the machine has not had any other major problems. I make sure to conduct regular maintenance on time, ensuring that filters, oils, and other parts are replaced promptly. I always use original parts, as this ensures the machine's long-term performance and reliability.

Conclusion

Overall, the Komatsu PC200-8 has performed well over the past three years. While there have been some issues, such as the fuel injector failure and the discolored hydraulic cylinders, the machine continues to run smoothly after proper repairs and maintenance. I will continue to follow up with the dealer to resolve the cylinder issue and keep the machine in top condition. I will continue to share updates on the machine's performance if anything new arises.

This experience has reinforced the importance of regular maintenance. Timely checks and part replacements are key to ensuring the machine runs efficiently and lasts longer.

|

|

|

| Experience Sharing: Non-Professional Use of an Excavator |

|

Posted by: MikePhua - 06-28-2025, 02:54 PM - Forum: Operator Talking

- No Replies

|

|

Recently, I started using an excavator for some home projects and would like to share my experience. I am not a professional operator, but this machine has been incredibly helpful for completing tasks around the house. Below are some insights and experiences from a non-professional user, which I hope will be useful to others with similar needs.

Reason for Purchase and Choice

The main reason I purchased the excavator was that I needed to handle some large-scale gardening and foundation work. There were several major projects around the house, such as digging a pond, clearing tree roots, and handling some groundwork. Given the high cost of renting an excavator for these tasks and the fact that I needed the equipment for an extended period, renting was not cost-effective. Therefore, I decided to buy a mini excavator.

After some research, I chose a small, non-professional model that suited my needs. When selecting the machine, I focused on factors like weight, ease of operation, and maintenance requirements. This machine is relatively simple and user-friendly, which makes it ideal for someone like me without a professional background.

Initial Impressions of Use

When I first started using the excavator, I was operating it entirely by intuition, without any formal training. Fortunately, the controls are relatively simple, and the user manual was clear and easy to follow. After reading the manual, I quickly got the hang of basic operations and started with some simple tasks.

The operation of the mini excavator was not difficult for a beginner, especially in open spaces. I adapted to the control levers quickly, and the digging and moving functions became smooth. Since the machine is compact, it’s very maneuverable and can easily access tight areas.

Challenges Encountered and Solutions

Although the operation was straightforward, I faced a few challenges as a non-professional user:

- Soil Types: The excavator performs differently in various types of soil. For instance, sandy and loose soils are easier to dig, while hard-packed soil or areas with many rocks require more time and effort. Initially, I underestimated the difficulty of digging in hard ground, and the machine occasionally struggled.

- Equipment Maintenance: Although the maintenance of the excavator is not complicated, I neglected a few small details. For example, regularly checking oil levels and cleaning filters are crucial for prolonging the life of the equipment. I later learned that timely maintenance can prevent breakdowns and keep the machine running smoothly.

- Operating Skills: As a beginner, I occasionally made mistakes, such as damaging the bucket or not digging precisely. Sometimes, I was too aggressive with the controls, which caused unnecessary vibrations, possibly leading to wear and tear. With practice, I improved my technique and reduced mistakes.

Summary

As a non-professional user, using the excavator initially had its challenges, but once I grasped the basic operations, work became much more efficient. The machine has been incredibly helpful for handling various foundation tasks around the house, saving me a lot of labor costs and rental fees. Most importantly, I found that the learning curve wasn’t as steep as I expected. With some practice and proper maintenance, the machine will continue to serve me well for years to come.

If you are like me, a non-professional operator, and need to handle some home projects, a small-scale mini excavator is a great investment. Before purchasing, I recommend doing thorough research and considering your specific needs and budget.

|

|

|

|