| Welcome, Guest |

You have to register before you can post on our site.

|

| Forum Statistics |

» Members: 43

» Latest member: Bob808

» Forum threads: 18,372

» Forum posts: 18,374

Full Statistics

|

| Online Users |

There are currently 104 online users.

» 1 Member(s) | 100 Guest(s)

Bing, Facebook, Google, MikePhua

|

|

|

| New CIMAF Excavator Crusher Head: Enhancing Efficiency and Crushing Power |

|

Posted by: MikePhua - 06-30-2025, 04:18 PM - Forum: Equipment Parts , Attachments & Tools

- No Replies

|

|

Recently, we introduced the new CIMAF excavator crusher head, a high-performance tool designed to enhance operational efficiency and crushing capabilities. As project demands increase, having an efficient and reliable crusher head has become an essential part of our work.

The CIMAF crusher head is renowned for its durability and powerful crushing force, making it especially effective for handling hard rocks and concrete. It maintains stable performance under high pressure and heavy load conditions, significantly boosting productivity at construction sites. Whether for demolition tasks or rock crushing, this crusher head tackles the job with ease, allowing projects to progress more efficiently.

Unlike traditional crusher heads, the CIMAF model uses advanced technology to reduce maintenance costs and extend service life. Its efficient hydraulic system and powerful crushing force ensure each operation is completed swiftly, while minimizing wear and tear on the equipment and lowering maintenance frequency.

On the operational side, this crusher head is designed for ease of use. It features a straightforward control system, allowing operators to manage the crushing process with precision, reducing human error and improving work efficiency. Additionally, the noise and vibration levels during operation are effectively controlled, enhancing both operator comfort and safety.

In terms of safety, the CIMAF crusher head is equipped with several advanced protective features, effectively preventing overloads and damage to the equipment, ensuring a safe and smooth work environment. Its high reliability minimizes the risk of unexpected failures, providing strong support for project progress.

In summary, the addition of the CIMAF excavator crusher head will significantly enhance both the efficiency and safety of our operations. With its exceptional performance, low maintenance costs, and high reliability, it will become a key asset in our projects, helping us complete construction tasks more quickly and accurately.

|

|

|

| New E37C Excavator with KLAC E-Quick Connect System: Enhancing Flexibility and Effici |

|

Posted by: MikePhua - 06-30-2025, 04:17 PM - Forum: Equipment Parts , Attachments & Tools

- No Replies

|

|

Recently, we introduced a brand-new E37C excavator, equipped with the KLAC E-Quick Connect system, aimed at boosting efficiency and versatility on our job sites. The addition of this new equipment will provide increased flexibility, especially in scenarios where quick attachment changes and higher operational efficiency are crucial.

The E37C excavator is a high-performance compact machine designed for a wide range of construction tasks. Its powerful engine and compact design make it ideal for working in confined spaces, particularly on urban construction sites and in narrow working areas.

A standout feature of the E37C is the KLAC E-Quick Connect system. This system allows operators to quickly and easily swap attachments without leaving the cabin, greatly improving work efficiency. Traditional attachment changes often require significant time and manual intervention, but the KLAC E-Quick Connect system simplifies this process, making the machine more efficient and user-friendly.

Additionally, the hydraulic system of the E37C has been significantly improved to enhance job precision and responsiveness, allowing the machine to quickly adapt to various tasks. The machine's stability and powerful output enable it to handle heavy-duty tasks with ease while maintaining high durability for long-term use.

For operators, the E37C’s cabin is another highlight. The cabin is spacious and comfortable, equipped with modern controls that make operation intuitive. Moreover, the advanced suspension system effectively reduces vibration and noise, improving operator comfort and safety, especially during long working hours.

Overall, the combination of the E37C excavator and the KLAC E-Quick Connect system enhances the machine's versatility and flexibility while optimizing safety and ease of use. This addition will be an essential part of our projects, helping to complete complex tasks efficiently.

|

|

|

| Master Jing and His Hyundai R60-7 Excavator: A Six Thousand-Hour Experience |

|

Posted by: MikePhua - 06-30-2025, 01:48 AM - Forum: Operator Talking

- No Replies

|

|

On July 24, 2014, our editorial team visited the East Ba construction equipment market in Beijing to conduct user interviews. The weather was favorable, but many pieces of equipment were still parked along the roadsides, including small to medium-sized excavators, wheeled excavators, loaders, cranes, and other construction vehicles. During the visit, we had the opportunity to interview a local excavator owner, Mr. Jing, whose insights on the market and his Hyundai R60-7 excavator were invaluable.

Changing Market Conditions

Mr. Jing shared that the excavator market has seen a steady decline in recent years. From 2008 to 2012, the market was booming, but starting in 2013, things began to slow down. At his peak, Mr. Jing owned up to four machines, but due to the market downturn, he has gradually sold off some of his equipment. Currently, he only operates a Hitachi 50 mini-excavator and a Sunward 18 micro-excavator.

Equipment and Work Practices

Mr. Jing started his career in automotive repair and eventually transitioned to excavator repairs. After gaining experience and understanding the excavator market, he decided to enter the business full-time. Over the years, he has purchased a variety of machines, including Hyundai, Zhenyang, and Sunward. In 2011, he purchased the Hyundai R60-7 mini-excavator, which has become his primary working machine.

Initially, Mr. Jing did not know how to operate an excavator, so he hired skilled operators. While he has since learned to drive the machines, he still prefers to have professional drivers operate the equipment while he focuses on finding work and managing his business.

Decision to Purchase the Hyundai R60-7

Before purchasing the Hyundai R60-7, Mr. Jing considered several brands, including Komatsu, Hitachi, and Hyundai. After conducting extensive research, including speaking with industry colleagues and evaluating fuel consumption and long-term maintenance costs, Mr. Jing decided that Hyundai offered the best balance of price and performance. The Hyundai R60-7 was competitively priced compared to other brands, and the model’s good reputation for reliability and fuel efficiency sealed the deal.

Equipment Performance and Usage

- Work Conditions

Mr. Jing primarily uses his Hyundai R60-7 for urban side jobs, including tasks like urban landscaping, backfilling, and municipal projects. For these jobs, the mini-excavator is often required to break through concrete or asphalt surfaces, so he had the machine equipped with a breaker line and a hydraulic hammer. However, breaker work is not as frequent, and most of the time, the machine uses a bucket for earthwork.

- Work Efficiency

Although Mr. Jing mentioned that the Hyundai R60-7 is somewhat slower than comparable models from Komatsu and Hitachi—especially in terms of swing speed and boom lifting speed—he noted that this doesn’t present a significant issue during regular work. The machine performs well on its own, and while it might be slightly slower in comparison, it still handles tasks like breaking concrete effectively. The slower speed is especially noticeable when the Hyundai works alongside other machines, but it doesn't pose a major problem when the excavator operates solo.

- Fuel Consumption

As a machine primarily used for short jobs, fuel consumption can vary, depending on the nature of the work. When completing lighter tasks, such as leveling city landscaping areas, fuel consumption is minimal. On days when the machine is required to perform more intensive work, like breaking through tough soil or asphalt, fuel consumption increases. On average, Mr. Jing spends around 200 RMB per day on diesel fuel when the machine operates for eight hours. This is considered quite efficient when compared to similar machines in its class.

- Product Performance

At nearly 6,000 hours, Mr. Jing's Hyundai R60-7 has performed well with very few major issues. The main complaints involve the air conditioning and the skylight. The air conditioning system had problems early on, requiring the replacement of the compressor, and later, some oil pipes had to be changed. By the 3,000-hour mark, the air conditioning was malfunctioning again, so Mr. Jing decided to replace the compressor with a non-original part. Fortunately, this solution worked well.

The skylight, however, proved to be less than ideal in terms of sealing. It leaked during rain, which wasn’t a major issue given Beijing’s relatively dry climate. Nonetheless, it was an inconvenience that could be bothersome during heavy rainfall.

- Engine and Hydraulic Systems

In terms of engine performance and the hydraulic system, Mr. Jing expressed satisfaction. The engine hasn’t shown signs of burning oil or leaking fluids, and the machine’s hydraulic power remains strong, similar to when the machine was new. The hydraulic oil was changed once, but the main pumps, control valves, travel motors, and swing motors have all operated smoothly without requiring significant repairs.

Dealer and After-Sales Service

Mr. Jing purchased his Hyundai R60-7 through Beijing Rui Zhidao Machinery Equipment Co., Ltd., a Hyundai dealer in Beijing. The dealership provides after-sales service for the first 2,000 hours or one year. During the warranty period, the company proactively performs maintenance services. They contact Mr. Jing in advance to schedule service visits, ensuring that the machine is kept in good working condition.

After the warranty period, Mr. Jing opted to perform the maintenance himself, following the recommended maintenance intervals in the service manual. He buys original oils and hydraulic fluids, but for filters (such as air, oil, and fuel filters), he purchases aftermarket parts, which saves him a considerable amount of money.

Overall Evaluation and Future Plans

In conclusion, Mr. Jing expressed high satisfaction with his Hyundai R60-7 mini-excavator. He believes it is a reliable, cost-effective machine that offers good value for the money, especially considering its performance over 6,000 hours of operation. When asked about future purchases, Mr. Jing mentioned that, due to the current market downturn, he does not plan to purchase any new equipment in the near future. However, if the market improves, he would consider buying another Hyundai excavator.

Through this interview, we gained valuable insights into Mr. Jing’s experience with his Hyundai R60-7, as well as his views on the excavator market and the challenges faced by small business owners in the construction equipment industry.

|

|

|

| Exploring Excavator Ownership: A 13-Ton Machine Owner's Experience |

|

Posted by: MikePhua - 06-30-2025, 01:43 AM - Forum: Operator Talking

- No Replies

|

|

In July 2014, our editorial team visited the Dongba market in Beijing, a hub for construction equipment, to better understand the needs of excavator owners and their equipment usage. With the help of a friendly local operator, we quickly familiarized ourselves with the area and began our interviews.

The Excavator Market at Dongba

As we arrived at the market, we were greeted by a wide array of machinery, including both small and large crawler excavators, wheeled excavators (also known as rubber-tired excavators), backhoes, rollers, cranes, dump trucks, and other construction equipment parked along the roadsides. According to Mr. Xu, a local excavator operator, the market has been slower than usual this year, with fewer jobs compared to last year. When the weather is good, many machines head out to work, but during rainy days, the parking lot fills up quickly with idle equipment.

In our tour, we observed the ecosystem of the market—many repair shops, parts stores, gas stations, and construction sites are nearby. Some operators were resting in their machines while waiting for work, while others were busy maintaining their equipment.

Meet Mr. Xu: A Seasoned Excavator Operator

Mr. Xu, a 40-year-old operator from Northeast China, has been in the business since 2005. Starting with a joint venture, he bought his first excavator—a 60-ton wheeled machine. As his business grew, he bought a Hyundai 60W-7, but due to increasing demands, he hired a driver. By 2010, business was booming, and he decided to purchase a small car and sell his wheeled excavator. In the following years, Mr. Xu acquired a Komatsu PC130-7 and later a new SANY 140-8. He also invested in a flatbed truck and now employs two drivers. With a steady workflow, he has more time to relax, play cards, and spend quality time with his family.

Equipment Information: Komatsu and SANY Excavators

Mr. Xu’s SANY 140, purchased in 2013 for around ¥700,000 (with financing), features a Mitsubishi high-pressure common-rail engine and a 0.57 m³ bucket. With about 2,000 hours of use, the machine has required minimal maintenance. Mr. Xu appreciates the machine’s fuel efficiency and fast working speed. He values the support he receives from the dealership, even though a few minor issues were never addressed during the initial purchase due to a lack of a formal contract. This experience taught him the importance of having all terms in writing when buying equipment.

As for the Komatsu PC130-7, which he bought second-hand, Mr. Xu was satisfied with its performance. Powered by a direct-injection engine and manufactured in Jining, Shandong, the PC130-7 is known for its reliable hydraulic system and engine, both of which are imported. Fuel consumption is similar to the SANY 140, averaging ¥60–70 per hour. Mr. Xu was keen to show us the machine, which was working on a project at the time.

Business Operations

Mr. Xu’s machines mostly work on scattered jobs, with some larger projects mixed in. He charges by the "shift," with a typical 8-hour shift costing ¥1,500. Even for shorter jobs, he charges for a full shift. On average, he completes around 20 shifts per month, with no additional fees for transporting machines since most of his clients were former owners of wheeled excavators.

While Mr. Xu occasionally handles demolition jobs, his machines are not equipped with breakers, which are instead handled by friends in the industry. The market this year has been slower, with the busy seasons running from March to May and from September to November.

Machine Maintenance and Strategy

Having been in the business for nearly a decade, Mr. Xu knows how to maintain his equipment well. He emphasizes the importance of regular maintenance, especially with the high-quality Mobil engine oil he uses. While he typically uses aftermarket parts for repairs, he prefers original parts for critical components like air filters. He mentioned that genuine parts, although expensive, offer superior quality—he recalled how the original filter’s seams were perfectly sealed.

At the June 19th auction in Beijing, Mr. Xu attended as part of the Iron Baby buyer group and considered buying a smaller excavator for future needs. He believes that as large-scale construction projects wind down, the demand for smaller excavators will grow, along with the promotion of various attachments.

The Workforce

Mr. Xu currently employs two drivers, both in their early 20s. One has been with him for five years, and the other has three years of experience. Despite the relatively low wages of ¥4,500 per month (with lodging provided), Mr. Xu values his drivers' responsibility and loyalty. He gives them an annual bonus of ¥2,000–3,000 and takes on the responsibility of transporting machines between sites himself, showing that mutual understanding is key to their relationship.

Conclusion

Mr. Xu’s journey in the excavator business has not been without challenges, especially with market fluctuations and a lack of formal contracts in the past. However, he remains optimistic about the future. He is confident that with careful management and the right equipment, his business will continue to thrive. Mr. Xu’s story is an excellent reminder for equipment owners to stay proactive, maintain good relationships with their workers, and ensure that all agreements are clearly documented.

We sincerely thank Mr. Xu for sharing his valuable insights and wish him continued success in his business. As for future excavator owners, this visit has been insightful, and we look forward to learning more from other machine owners to better understand their needs and experiences in the field.

|

|

|

| The Practical Benefits of Excavator Window Tinting: A Test and Analysis |

|

Posted by: MikePhua - 06-30-2025, 01:42 AM - Forum: Operator Talking

- No Replies

|

|

During the hot summer months, especially in cities like Beijing where temperatures can reach 40°C, excavator operators face immense pressure to work under the scorching sun. As the heat intensifies, the topic of window tinting for excavators often arises, sparking debates among equipment owners. Proponents argue that window tinting helps reduce heat and eases the strain on air conditioning, while opponents claim it may hinder visibility, particularly during nighttime operations. To shed light on this debate, we conducted a comprehensive test to evaluate the actual benefits of excavator window tinting.

The Test Setup

To thoroughly assess the impact of window tinting, we partnered with Li Hongliang, a seasoned excavator operator in Hebei Xianghe, who owns two Caterpillar 306E excavators. One of the machines had window tint applied, while the other remained untinted. This allowed us to compare the performance of both machines under similar conditions.

Selecting the Right Film

Before we started the tinting process, we sought advice from a professional shop on how to select the right window film. They shared several methods to assess film quality, which we categorized as follows:

- Look

High-quality window film offers excellent clarity and transparency, typically over 90%. The color of the film does not significantly affect visibility, even in low-light conditions. In contrast, low-quality films often have a cloudy appearance, especially noticeable at night or during rain.

- Smell

Premium films use non-toxic adhesives that are odorless. Low-quality films, on the other hand, often have strong, unpleasant odors due to high levels of solvents like benzene, which can be harmful to health.

- Touch

High-quality films feel thick and smooth, while inferior films are thin, flimsy, and prone to wrinkling.

- Look Again

A good film will be bubble-free and smooth. Poor films tend to form tiny bubbles and wrinkles due to impurities in the adhesive.

After choosing the right film, we also learned some additional tips from the supplier, such as using a fingernail to scratch the film (low-quality films will lose color), and that the tint’s heat resistance depends on the thermal layer, not the color layer.

The Tinting Process

Before applying the film, it is crucial to prepare the vehicle properly. Measuring the window area ensures that enough film is purchased to avoid waste. Additionally, it’s best to apply window tint on cloudy days or after rain, as this minimizes dust and floating particles that can create bubbles. Applying the tint under direct sunlight can cause the film to wrinkle or bubble, negatively affecting its appearance and performance.

Post-Tinting Testing

We conducted temperature and light intensity tests on both the tinted and untinted excavators from 12 PM to 2 PM, the hottest part of the day. The outdoor temperature during testing was 30°C.

- Untinted Excavator Test

- Seat headrest temperature before exposure: 44.3°C

- Outdoor sunlight intensity: 647W/㎡

- Light intensity through the window: 514W/㎡

- Seat headrest temperature after 30 minutes of exposure: 49.4°C

- Tinted Excavator Test

- Seat headrest temperature before exposure: 36.6°C

- Outdoor sunlight intensity: 665W/㎡

- Light intensity through the window: 225W/㎡

- Seat headrest temperature after 30 minutes of exposure: 47.7°C

Results Analysis

The test results clearly show that the tinted excavator experienced a significant reduction in light intensity. The light passing through the tinted window was reduced by 440W/㎡, much lower than the untinted machine. After 30 minutes of exposure, the seat headrest temperature in the tinted excavator was 1.7°C lower than the untinted one, demonstrating the tangible heat reduction benefit of window tinting.

Operator Feedback

We also interviewed Li Hongliang, the operator, to get his perspective on the use of tinted windows for excavators. He mentioned that tinting noticeably reduces the strain on the air conditioning system, helping it cool the cabin faster and more efficiently, leading to lower fuel consumption. Additionally, he observed that tinted windows reduce glare, making it easier on the eyes and improving comfort during long shifts. As for nighttime operations, he assured us that good lighting from the headlights compensates for any minor loss of visibility caused by the tint.

Conclusion

From our tests and operator feedback, it is clear that window tinting for excavators provides several benefits. Not only does it help in heat reduction, but it also reduces the workload on air conditioning, improving fuel efficiency. Additionally, it minimizes glare, enhancing comfort during the day. Although the temperature difference may seem small (1.7°C), this shows that tinting does have a noticeable effect on slowing down the cabin's temperature rise. Given the benefits, especially during long hours under the sun, window tinting is indeed a worthwhile investment for excavators.

|

|

|

| Considering the Purchase of a New Holland EC35 Excavator: Key Considerations |

|

Posted by: MikePhua - 06-30-2025, 01:38 AM - Forum: Operator Talking

- No Replies

|

|

If you’re thinking about buying a New Holland EC35 excavator, there are a few key things to consider before moving forward. Here are some of the concerns I had while evaluating this used equipment, and the insights shared by others in the process:

1. Cylinder Repacking

One of the cylinders on the machine appears to be leaking, which raises a valid concern about the cost of repacking it. Repacking a cylinder can be expensive, depending on the severity of the leak and whether the cylinder itself is damaged. It's essential to factor in the cost of repairs for this when assessing the overall value of the machine.

2. Hydraulic Tank Leak

There’s a tank located under the hydraulic manifold that seems to be leaking. This could be a significant issue, especially if it's affecting the hydraulic system. The cost of repairing or replacing the tank can vary widely, depending on its size and the extent of the damage. If the leak is minor, a simple seal replacement might do, but if the tank is severely damaged, it may need to be replaced entirely.

3. Engine Replacement

The engine has been replaced with an Isuzu engine. While Isuzu engines are generally known for their reliability, it’s important to assess how well the engine integrates with the rest of the excavator's systems. If the engine was installed correctly, it could be a good choice, but it's always wise to inspect the engine’s condition thoroughly and check for any issues related to the retrofit.

4. Price and Seller Transparency

The seller is asking $12,500 for the excavator, but there are some concerns about the transparency of the transaction. While the seller may not seem overtly dishonest, it’s important to approach with caution. When questioned about potential issues, the seller seemed to downplay them, which can be a red flag. For example, the seller had a Bobcat 331 listed for sale but had to stop the sale after a drive motor blew while loading it onto a truck. Such instances raise questions about the seller’s reliability.

5. Vehicle History and Theft Concerns

Before committing to any used equipment purchase, it's wise to run a background check, especially if the seller seems "sketchy." One option is to have the serial number of the excavator checked by local authorities to ensure that it hasn’t been stolen or involved in any illegal activity. This step could help prevent unexpected issues later on.

Conclusion

While the New Holland EC35 excavator might offer good value at first glance, potential buyers should proceed carefully. It’s crucial to assess the machine's mechanical condition thoroughly, consider the cost of repairs (such as cylinder repacking and hydraulic tank repairs), and verify the legitimacy of the transaction. Always remember: if something feels off during the inspection or negotiation process, it might be best to walk away.

In summary, a little caution, proper inspection, and background checks can go a long way when purchasing used equipment like the New Holland EC35.

|

|

|

| How to Choose the Right Long Boom Configuration for Your Excavator |

|

Posted by: MikePhua - 06-30-2025, 12:18 AM - Forum: Operator Talking

- No Replies

|

|

The long boom is a vital attachment for excavators, designed to extend their reach and versatility. It is a custom piece that significantly enhances the machine's performance and is often chosen based on specific project needs. Here is a guide on how to select the right long boom configuration for your excavator:

1. Types of Long Booms

Excavator long booms are typically classified into two main types: - Two-Stage Long Boom: The boom can extend up to 13-26 meters and is most commonly used for earthworks, deep trenching, and long-distance dredging tasks.

- Three-Stage Long Boom: These booms can extend up to 16-32 meters and are often used in high-rise building demolition and similar heavy-duty tasks.

2. Key Considerations for Selecting a Long Boom

When selecting a long boom, the weight class of your excavator plays a key role in determining the configuration. Here are the most common configurations based on the machine's weight class:- For 10-16 Ton Excavators:

- Extension: Up to 13 meters

- Configuration: 1 bucket, 1 bucket cylinder, 6 pins, 4 high-pressure hoses, 3 grease pipes, 1 link assembly, and a counterweight (1-3 tons). The arm is configured with a 7.1-meter long boom and a 5.9-meter long arm.

- For 20-22 Ton Excavators:

- Extension: Up to 15.38 meters

- Configuration: 1 bucket, 1 bucket cylinder, 6 pins, 4 high-pressure hoses, 3 grease pipes, 1 link assembly, and a counterweight (1-3 tons). The arm is configured with an 8.22-meter long boom and a 7.16-meter long arm.

- For 20-25 Ton Excavators:

- Extension: Up to 18 meters

- Configuration: 1 bucket, 1 bucket cylinder, 6 pins, 4 high-pressure hoses, 3 grease pipes, 1 link assembly, and a counterweight (1-3 tons). The arm is configured with a 10-meter long boom and an 8-meter long arm.

- For 25-34 Ton Excavators:

- Extension: Up to 20 meters

- Configuration: 1 bucket, 1 bucket cylinder, 6 pins, 4 high-pressure hoses, 3 grease pipes, 1 link assembly, and a counterweight (1-3 tons). The arm is configured with an 11-meter long boom and a 9-meter long arm.

- For 35-40 Ton Excavators:

- Extension: Up to 22 meters

- Configuration: 1 bucket, 1 bucket cylinder, 6 pins, 4 high-pressure hoses, 3 grease pipes, 1 link assembly, and a counterweight (1-3 tons). The arm is configured with a 12-meter long boom and a 10-meter long arm.

- For 40-50 Ton Excavators:

- Extension: Up to 26 meters

- Configuration: 1 bucket, 1 bucket cylinder, 6 pins, 4 high-pressure hoses, 3 grease pipes, 1 link assembly, and a counterweight (1-3 tons). The arm is configured with a 14-meter long boom and a 12-meter long arm.

3. Compatible Excavator Brands

Long booms are available for various excavator brands. Some of the well-known brands that offer long boom configurations include:- Caterpillar (CAT)

- Komatsu (PC)

- Hitachi (EX, ZAX)

- Kobelco (SK)

- Daewoo (Doosan) DH

- Hyundai ®

- Kato (HD)

- Case (CX)

- Sumitomo (SH)

- Volvo (EC)

- LiuGong

- Yuchai

- SANY

- XCMG

4. Selecting the Right Long Boom

When selecting the right long boom, consider the specific needs of your project. Longer booms are suitable for tasks that require greater reach, such as demolition, deep digging, and material handling over long distances. Ensure that the boom’s extension and the excavator’s lifting capacity match your project’s requirements.

In conclusion, choosing the right long boom configuration will depend on factors such as the size of your excavator, the nature of your work, and your reach requirements. By selecting the correct attachment, you can enhance the performance and efficiency of your excavator in various applications.

|

|

|

| Nine Key Considerations for Replacing Diesel Engine Cylinder Head Gaskets |

|

Posted by: MikePhua - 06-30-2025, 12:17 AM - Forum: Excavator Repair Shop & Troubleshooting

- No Replies

|

|

When replacing the cylinder head gasket on a diesel engine, attention to detail is essential to ensure optimal performance and prevent further issues. Here are nine key points to follow during the process:

1. Ensure Correct Cylinder Sleeve Height

The top surface of the cylinder sleeve shoulder must be higher than the engine block surface by the specified distance. If the cylinder sleeve shoulder is too high, the lower surface of the sleeve can be ground down to achieve the correct height. If it is too low, copper shims can be used at the contact surface to compensate.

2. Retighten Cylinder Head Bolts After Initial Operation

For newly installed or refurbished engines, after running for 240-250 hours, it is important to re-tighten the cylinder head bolts.

3. Tighten Cylinder Head Bolts in Sequence

Always tighten cylinder head bolts in the specified sequence, in three stages. The torque should be neither too high nor too low, and all bolts must be tightened to the same torque specification.

4. Ensure Proper Alignment of Bolts

When inserting standard bolts into the engine block, ensure that the alignment is perpendicular to the engine block. The misalignment should not exceed 1mm.

5. Replace Broken or Worn Bolts and Nuts

Replace any broken or worn-out bolts and nuts promptly. After tightening the cylinder head bolts into the engine block, ensure that no bulging occurs on the engine block surface.

6. Verify Engine Block Surface Flatness

During installation, carefully check the flatness of the engine block surface. Any dents or pitting near the water jacket holes should be sealed with copper shims to prevent leaks.

7. Choose the Correct Gasket Size

Ensure that the cylinder head gasket is the correct size and that the asbestos material is uniformly distributed. Check that the copper seals around the cylinder holes and water jacket holes are properly compressed without any damage, such as lifting or falling off. When removing old gaskets, be cautious not to damage them, and inspect the new gasket for any defects before installation. If a gasket cannot be repaired, it should be replaced.

8. Maintain Proper Engine Temperature

Ensure that the engine operates at a temperature between 75-95°C. If the engine temperature exceeds this range due to poor cooling or delayed fuel supply, immediately stop the engine and resolve the issue. Avoid running the engine under excessive loads for extended periods.

9. Prevent Gasket Burnout at Water Jacket Holes

To prevent the gasket from burning out at the three water jacket holes on the engine block's right side, modify the small circular holes on the gasket to align with the shape of the water jacket holes on the cylinder head. Then, use copper shims to compress or weld them into place. This reduces water flow resistance and protects the gasket from coolant damage.

By following these steps carefully, the diesel engine will have better longevity and reliability, ensuring smooth operation after the gasket replacement.

|

|

|

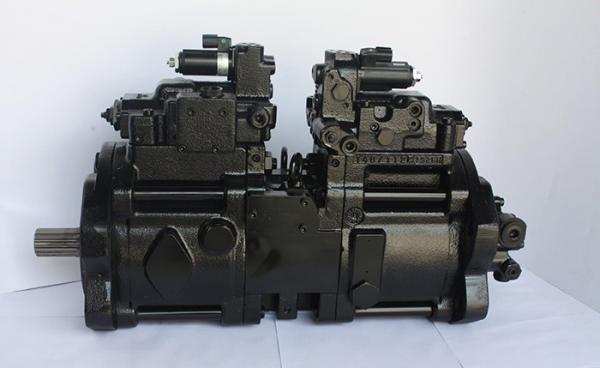

| Hydraulic Pump Replacement: A Critical Surgery for Excavators |

|

Posted by: MikePhua - 06-30-2025, 12:13 AM - Forum: Excavator Repair Shop & Troubleshooting

- No Replies

|

|

For an excavator, the hydraulic pump is the heart of its hydraulic system. When this vital component fails and needs to be replaced, it’s akin to a heart transplant in humans—an extensive and delicate procedure. Besides selecting the right hydraulic pump and a skilled technician, there are many post-replacement considerations. Just like human heart surgery, close monitoring after the procedure is essential.

1. Monitor the Operation of the New Pump for Three Months

After replacing the hydraulic pump, it's crucial to observe the machine during the break-in period. Pay attention to unusual vibrations, odd noises, or abnormal temperature changes in the oil. If any irregularities occur, diagnose the issue promptly to determine the underlying cause.

2. Avoid Load Immediately After Starting the New Pump

When starting the new hydraulic pump, avoid applying a load right away. Allow the machine to run without load for a period, especially in colder temperatures, to ensure sufficient warm-up time. Only gradually add load once the hydraulic circuit is confirmed to be circulating properly. During this time, carefully monitor the machine's performance.

3. Monitor Hydraulic Oil Temperature

After running the new pump for a period, observe the temperature changes in the hydraulic oil. Test the maximum and minimum oil temperatures under typical working conditions. By comparing the results over time, you can verify if the oil level is adequate and whether the hydraulic oil and cooling system are compatible.

4. Pay Attention to Noise from the Hydraulic Pump

Since the new hydraulic pump hasn’t undergone wear, it may produce unusual sounds if the hydraulic oil is dirty, lubrication is inadequate, or the load is too high. It’s important to detect such noise promptly and make necessary adjustments.

5. Observe the Machine's Movements

If the new hydraulic pump isn’t installed properly or the parameters don’t match, it may not be noticeable during idle operations. Therefore, when the machine starts actual work, pay extra attention to the smoothness of the excavator's movements and whether the power output is sufficient.

6. Adjust Hydraulic Valves After Replacement

Before the pump replacement, the owner or technician may have made adjustments to some hydraulic system valves. After installing the new pump, it’s essential to recalibrate the relevant valves to ensure they operate correctly and eliminate potential faults.

7. Regularly Check the Filter and Hydraulic Oil

After the pump replacement, regularly inspect the filters in the hydraulic circuit. Analyze the type and amount of contaminants on the filter screen to predict the source of potential failures. Additionally, check the hydraulic oil once a month to assess any degradation, discoloration, or contamination, which may indicate underlying issues.

Replacing a hydraulic pump is a significant task that requires careful attention both during and after the replacement. Proper monitoring and maintenance will ensure the excavator performs at its best and prevent any unforeseen issues from arising.

|

|

|

| A Beginner's Guide: How to Choose the Right Excavator Bucket |

|

Posted by: MikePhua - 06-30-2025, 12:10 AM - Forum: Equipment Parts , Attachments & Tools

- No Replies

|

|

The bucket is one of the most important attachments on an excavator, with many different types and shapes designed for various functions. Choosing the right bucket can significantly enhance work efficiency. So, how do you pick the perfect bucket for your needs? Here are some practical tips to help you make an informed decision.

1. How to Choose the Structure and Material?

Excavator buckets (also known as digging buckets) are generally divided into two types based on their working method: standard buckets and reverse buckets. In this article, we focus on the commonly used reverse bucket. The structure of a reverse bucket is relatively simple and mainly consists of the following components: - Tooth seat plate

- Bottom plate

- Side plate

- Wall plate

- Mounting ear plate

- Back plate

- Bucket ears

- Bucket ear cover

- Bucket teeth

- Tooth seat

- Guard plate or bucket corner

These components can be adjusted based on the specific working conditions, and parts like edge plates and guard plates can be added or reduced as needed.

When it comes to materials, high-quality buckets are generally made of Q345B and HQ60 steel plates. Some premium buckets may use Swedish Hardox steel, which is more expensive. It's important to avoid buckets made primarily from A3 steel, particularly for the tooth seat plate and bottom plate, as these parts experience frequent friction and A3 steel wears out quickly.

2. How to Assess the Durability of the Bucket?

The most vulnerable parts of the bucket are the tooth seat plate and the connection between the bucket ear plate and the back plate. While the design of the tooth seat plate has less impact, the welding technique and material choice are critical for durability. To improve stability, the back plate should be designed to be longer, which increases the weld area and strengthens the connection between the bucket ear plate and the bottom part.

Additionally, welding quality significantly affects the bucket's strength. When choosing a bucket, check the number, quality, and alignment of the welds to ensure reliability.

Looking at the bucket from the front, you’ll notice that the opening is typically rectangular. A rectangular shape is less stable, so high-quality buckets reinforce the internal structure by adding four corner supports. Similarly, other parts, such as the bucket ear plates, can also include reinforcement ribs to further strengthen the design.

3. How to Select Bucket Attachments?

Excavator buckets have several attachments that often need replacing, including bucket ear covers, corner wear plates, and bucket teeth. Some manufacturers may use substandard attachments to reduce costs, so it’s essential to carefully inspect these parts during the purchasing process.

- Bucket Ear Covers

Originally, bucket ear covers were cast, but due to their lack of toughness, they would often break during work. Today, most manufacturers use 45# steel to make steel ear covers, which are much more durable. Even if they crack, they can be welded and repaired.

- Corner Wear Plates and Bucket Teeth

Corner wear plates and bucket teeth primarily bear the brunt of impact and wear, so they must have high wear resistance and hardness. These parts are typically made from high-carbon steel. To check the quality of cast parts, a simple method is to tap on them. High-quality castings produce a crisp sound, while low-quality ones have a dull, muted sound.

By understanding the structure, materials, durability, and attachment selection standards for excavator buckets, you can make a more informed choice, increase work efficiency, and extend the life of your equipment.

|

|

|

|