| Welcome, Guest |

You have to register before you can post on our site.

|

| Forum Statistics |

» Members: 43

» Latest member: Bob808

» Forum threads: 15,290

» Forum posts: 15,292

Full Statistics

|

| Online Users |

There are currently 100 online users.

» 0 Member(s) | 99 Guest(s)

Bing

|

|

|

| Using and Troubleshooting the Vibrascreen Screening Machine |

|

Posted by: MikePhua - 07-07-2025, 12:37 AM - Forum: Operator Talking

- No Replies

|

|

Overview of the Problem

The Vibrascreen screening machine is a crucial piece of equipment used for grading and separating materials in industries such as mining, construction, and recycling. However, problems such as insufficient vibration or poor screening performance can occur during operation. These issues can reduce productivity and lead to equipment failure, making it necessary to troubleshoot and resolve the problems promptly.

Common Issues and Causes

- Insufficient Vibration

If the Vibrascreen screening machine lacks proper vibration, it could be due to a faulty vibration motor, loose springs, or damaged cushions. Insufficient vibration will lead to uneven screening and reduced screening efficiency.

- Clogged Screens

Clogging of the screen is another common issue. Larger particles or sticky materials can easily clog the screen, resulting in reduced screening performance.

- Uneven Screening

Uneven screening can be caused by factors such as improper screen tension, material flowability, or vibration frequency. If the screen tension is too loose or too tight, it will affect the screening quality.

- Overheated or Damaged Motor

An overheated or damaged vibration motor is a major cause of insufficient vibration. Overuse or lack of lubrication can accelerate the wear of the motor, eventually causing it to fail.

Solutions

- Inspect the Vibration Motor

Regularly check that the vibration motor is operating properly, ensuring there are no unusual noises or overheating issues. If a problem is detected, repair or replace the motor as needed.

- Check the Springs and Cushions

Inspect the springs and cushions for looseness or damage. Make sure they are properly supporting the vibration function of the equipment. Tighten or replace them as necessary.

- Clean the Screen

Periodically clean the screen, especially if clogging occurs. When cleaning, be careful not to apply excessive force to avoid damaging the screen. For sticky materials, consider using a screen with larger mesh openings.

- Adjust the Screen Tension

Adjust the screen tension according to the material characteristics to ensure optimal screening performance. If necessary, reinstall or replace the screen.

- Check the Lubrication System

Ensure the lubrication system for the vibration motor and other moving parts is functioning correctly. Regularly add lubricant to reduce friction between components and extend the equipment's lifespan.

Conclusion

During operation, the Vibrascreen screening machine may experience issues such as insufficient vibration, screen clogging, or uneven screening. By regularly inspecting the vibration motor, springs, cushions, and screen, cleaning clogs promptly, adjusting screen tension, and ensuring proper lubrication, you can improve screening efficiency and extend the equipment’s operational life.

|

|

|

| The History of the First Hydraulic Excavator:Who invented the excavator? |

|

Posted by: MikePhua - 07-07-2025, 12:36 AM - Forum: Operator Talking

- No Replies

|

|

The concept of using hydraulic power for more efficient digging in excavators began to take shape in the 1880s. One of the earliest attempts to incorporate hydraulic technology into excavation equipment was the 1882 excavator built by Sir W. G. Armstrong & Company in England. This machine was used in the construction of the Hull Docks. However, unlike modern excavators that use hydraulic fluid, this machine operated with water as the hydraulic fluid. Additionally, it was not a fully hydraulic machine, but a hybrid design that used cables to operate the bucket and a hydraulic cylinder to operate a set of multiplying sheaves. Unfortunately, this idea was not successful, and neither was a similar machine built in 1914 by Frank F. Armstrong for the Penn Iron Mining Company in the United States.

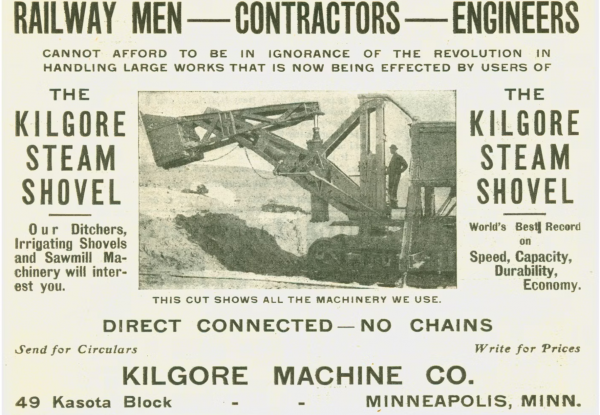

The First True Hydraulic Excavator: Kilgore's Innovation

The first all-hydraulic excavator was created by the Kilgore Machine Company in 1897. This machine, called the Direct Acting Excavator, used four direct-acting steam cylinders for all bucket functions, eliminating the need for cables or chains, which were commonly used in conventional excavators at the time. This design marked a significant breakthrough in hydraulic excavation technology.

Kilgore’s design had several notable advantages:- The excavator was made almost entirely of steel, making it robust and durable.

- All movements, including the full stroke of each cylinder, were cushioned, preventing shock or damage even when operating at high speeds and full stroke.

- The use of steam cylinders for all bucket functions provided a greater range of motion than typical cable-operated machines, allowing the bucket to crowd horizontally and manipulate larger obstacles such as boulders with greater ease.

Kilgore’s Direct Acting Excavator: Advanced Features

Kilgore’s Direct Acting Excavator was ahead of its time in many ways:- The machine had equal power in all movements, allowing the bucket to be withdrawn under load without having to lift it to the top to clear the cut, a major advantage over conventional shovels.

- In the event the shovel derailed, the machine’s design allowed for the full application of power to lift it back onto the rails, a feature not seen in traditional machines.

- The dipper could be forcefully shaken with the cylinders to dislodge materials jammed inside, improving operational efficiency.

Moreover, by eliminating complex parts such as chains, cables, sheaves, drums, friction clutches, gears, and hoisting engines, the machine’s design was simplified with fewer working parts. The operation was equally straightforward, controlled by two levers, with the engineer’s hand motion directly duplicated at the bucket. Additionally, instead of using a trip rope or lever, a foot pedal was used to dump the bucket, foreshadowing the full-revolving excavators that would emerge in the 20th century.

Kilgore’s Economic Advantage and Limited Success

Kilgore also marketed its machine’s economy of operation, noting that the cylinders required less steam, which translated into reduced fuel and water consumption compared to other traditional shovels. Moreover, the engineer operated all functions of the machine, eliminating the need for a second crew member to operate the dipper as in conventional machines.

Kilgore produced several railroad shovels with dipper capacities of 1-1/4 and 2-1/2 yards. They also created traction wheel shovels, steam ditchers for land reclamation and irrigation, and dipper dredges. Despite the advanced concepts, Kilgore’s Direct Acting Excavator met with limited success due to various factors, including competition from other established technologies and the limitations of the design at the time.

Conclusion

While Kilgore’s Direct Acting Excavator was a groundbreaking innovation in hydraulic technology, it did not achieve widespread commercial success. Nevertheless, it played an important role in the development of modern hydraulic excavators. The innovations introduced in this machine, such as cable-free operation, direct-acting cylinders, and more efficient energy use, laid the groundwork for future advancements in the field of excavation machinery.

|

|

|

| Weight of the Case 40-4 Trencher |

|

Posted by: MikePhua - 07-07-2025, 12:35 AM - Forum: Operator Talking

- No Replies

|

|

Overview of the Issue

Many people are curious about the weight of the Case 40-4 trencher, especially when considering transportation and operation. Knowing the exact weight of the equipment is crucial for assessing stability, traction, and transportation needs.

Weight of the Case 40-4 Trencher

The standard operating weight of the Case 40-4 trencher is approximately 10,000 pounds (around 4,536 kilograms). This weight applies to the base model without additional attachments. It provides a good balance between being heavy enough to offer stability and traction, yet not so heavy as to cause transportation difficulties.

Impact of Weight on Transportation and Operation

- Transportation Requirements

The weight of the trencher is a key factor in determining the transportation method. Depending on the equipment's weight, specialized transport vehicles may be required. If the trencher exceeds certain weight limits, transport permits may be necessary, and low-boy trailers may be needed for hauling.

- Operational Stability

The weight of the trencher directly impacts its stability during operation. Heavier machines offer better traction and stability, especially in challenging terrain and when working under heavy loads. Lighter machines, while more maneuverable, may experience stability issues when handling significant weight.

Conclusion

The Case 40-4 trencher has a standard operating weight of 10,000 pounds, making it suitable for a variety of tasks. Understanding the weight of the equipment is important for transportation planning and operational stability, helping users make more informed decisions when using the trencher.

|

|

|

| Analysis of CAT M Series Cab Door Issues |

|

Posted by: MikePhua - 07-07-2025, 12:33 AM - Forum: Operator Talking

- No Replies

|

|

Common Issues with CAT M Series Cab Doors

In CAT M Series machines, cab doors often experience issues such as not closing tightly or getting stuck. These problems can affect operator comfort and safety, and in some cases, may impact the machine's overall functionality. Common causes of these issues are found in the door locking mechanisms, hinges, or the door seals.

Potential Causes of the Problem

- Worn Door Hinges

With extended use, door hinges may become worn or loose, causing the door to not close or open properly. Loose hinges can misalign the door, preventing it from sealing correctly.

- Faulty Door Lock

A damaged or worn-out door lock is another common cause. If the lock doesn’t fully engage, the door won’t stay closed, affecting both safety and the door’s seal.

- Worn or Damaged Seals

The door seals on the cab can deteriorate over time, especially with prolonged exposure to the elements. Once cracked or damaged, the seals won’t provide a proper fit, allowing dust, dirt, and noise to enter the cab.

How to Troubleshoot and Repair

- Inspect Door Hinges

Begin by checking the door hinges for any visible wear or looseness. If you find the hinges are damaged or loose, tighten or replace them to ensure smooth door operation.

- Inspect the Door Lock Mechanism

Ensure the door lock is not stuck or damaged. Clean and lubricate any seized lock parts, and if the lock mechanism is heavily worn, replacement might be necessary.

- Check the Seals

Inspect the door seals, particularly around the door’s contact areas. If the seals are cracked, hardened, or missing, replace them to ensure the door closes properly and maintains a good seal.

- Check Door Alignment

Verify that the door and door frame are properly aligned. If the door is misaligned, adjustments to the frame may be required to improve the closing action.

Conclusion

The common issues with CAT M Series cab doors are typically related to worn door hinges, faulty locks, and damaged seals. Regular inspection and maintenance of these components can help prevent problems like improper sealing or difficulty closing, improving operator comfort and ensuring the machine operates effectively.

|

|

|

| Analysis and Solutions for Weak Boom Lift on Caterpillar 416 Backhoe |

|

Posted by: MikePhua - 07-07-2025, 12:33 AM - Forum: Operator Talking

- No Replies

|

|

Overview of the Problem

The Caterpillar 416 backhoe loader is experiencing weak boom lift performance during operations. Specifically, the bucket lacks the necessary lifting power, which affects the machine's ability to efficiently excavate or lift heavy loads. This issue can significantly impact work productivity and requires timely diagnosis and resolution.

Possible Causes

- Hydraulic System Issues

The hydraulic system plays a crucial role in providing lifting power for the boom. If there are problems such as hydraulic fluid leaks, low oil pressure, or blocked oil lines, it can lead to weak boom lift performance. This is one of the most common causes of the issue.

- Poor or Insufficient Hydraulic Oil

If the hydraulic oil is of poor quality or is insufficient, the hydraulic system may not perform optimally. Over time, contaminated or degraded hydraulic oil can lead to a reduction in system efficiency, which directly impacts lifting capabilities.

- Faulty Hydraulic Pump or Solenoid Valve

A malfunctioning hydraulic pump or solenoid valve can severely affect the flow and pressure of hydraulic oil, leading to inadequate lifting power. Worn hydraulic pumps or stuck solenoid valves are common issues that need attention.

- Wear and Tear on Mechanical Components

Mechanical parts such as the boom, arm, or hinge components may wear out over time, particularly under heavy use. Excessive wear on these parts can cause structural looseness, which reduces the machine's lifting capacity.

- Control System Issues

Problems within the control system, such as faulty control valves or sensors, can also result in insufficient hydraulic power being delivered to the boom, thereby affecting its lifting ability.

Solutions

- Inspect the Hydraulic System

Start by checking the hydraulic oil level and quality. If the oil is low or contaminated, replace it with fresh, high-quality hydraulic oil. Additionally, inspect the oil lines for any leaks and ensure that oil flows smoothly through the system.

- Check the Hydraulic Pump and Solenoid Valve

Inspect the hydraulic pump to ensure it is operating correctly and providing adequate flow and pressure. If the pump is damaged or worn out, it may need to be repaired or replaced. Similarly, check the solenoid valve to ensure it is not sticking or malfunctioning.

- Inspect Mechanical Components

Check the boom, arm, and hinge components for signs of wear or loosening. If any parts show significant wear, they should be replaced or repaired to restore proper lifting functionality.

- Examine the Control System

If the hydraulic system and mechanical components are functioning correctly, inspect the control system, including control valves and sensors. Ensure all electrical components are working properly. Replace or repair any faulty parts as needed.

Conclusion

Weak boom lift performance on the Caterpillar 416 backhoe can result from issues with the hydraulic system, poor hydraulic oil, faulty hydraulic pumps or solenoid valves, mechanical wear, or control system problems. By systematically troubleshooting and addressing each potential cause, you can restore the backhoe’s lifting power and ensure it operates efficiently.

|

|

|

| Starter Issues with the DT466 Engine in a 1984 S1900 |

|

Posted by: MikePhua - 07-07-2025, 12:32 AM - Forum: Operator Talking

- No Replies

|

|

Symptoms of Engine Starting Issues

In the 1984 S1900 truck equipped with the DT466 engine, some users have experienced difficulties when trying to start the engine. The engine may fail to respond or only show a faint reaction, despite the battery having adequate charge. This issue can be particularly troublesome in colder weather, where starting problems become more pronounced.

Common Causes of the Problem

The root cause of these starting issues is often linked to the electrical system or the condition of the starter motor. One common culprit is a faulty starter relay (or starter switch). If the relay fails to function properly, the starter motor may not receive the signal to engage. Additionally, issues with the starter motor itself—such as worn brushes or damage to the motor—can also prevent the engine from turning over.

Another potential cause is problems with the battery or cable connections. Even if the battery has sufficient charge, loose or corroded battery terminals can restrict the flow of current, impairing the starting process. Grounding issues or unstable voltage within the electrical system may also contribute to starting problems.

How to Troubleshoot the Issue

First, users should check the starter relay to ensure it is functioning correctly. A multimeter can be used to test the relay's switching function, verifying that it properly connects and disconnects the current. Next, inspect the starter motor for wear and tear. Worn brushes or damage to the motor may require the replacement of the starter motor.

Following that, check the battery and cable connections. Ensure that the battery terminals are clean and free from corrosion, and that the cables are securely fastened. If necessary, clean the terminals or re-tighten the connections to ensure smooth current flow.

Other Areas to Inspect

If the above steps do not resolve the issue, the vehicle's grounding system should be inspected. Check the condition of all ground connections to make sure they are secure and free from corrosion. Lastly, examine the voltage and current throughout the electrical system to ensure there is sufficient power to support engine startup.

Conclusion

Starter issues in the 1984 S1900 with the DT466 engine are often related to electrical system components. By systematically checking the starter relay, starter motor, battery connections, and grounding system, users can effectively diagnose and resolve the issue, restoring proper engine start functionality.

|

|

|

| Analysis and Solutions for C8500 Truck Not Starting |

|

Posted by: MikePhua - 07-07-2025, 12:32 AM - Forum: Operator Talking

- No Replies

|

|

The C8500 truck is experiencing an issue where the engine will not start. The main problem reported is that the engine is unresponsive and will not turn over, which can be very frustrating as it prevents the vehicle from being used for its intended work.

Common Causes

- Weak Battery

One of the most common causes of a no-start issue is a weak or dead battery. If the battery voltage is too low, the starter motor cannot receive enough power to turn the engine over.

- Starter Motor Failure

A malfunctioning starter motor can also prevent the engine from starting. It’s important to check the electrical connections to the starter motor to ensure it’s operating properly.

- Fuel System Issues

Problems within the fuel system, such as a malfunctioning fuel pump or a clogged fuel filter, can cause the engine not to start. Make sure the fuel lines are clear and that the fuel pressure is normal.

- Ignition System Failure

Issues with the ignition system, such as a faulty ignition switch or non-functional spark plugs, can also prevent the engine from igniting the fuel and starting.

- Blown Fuses or Faulty Relays

It’s important to check the fuses and relays associated with the starting system. A blown fuse or a faulty relay can stop the starting process altogether.

Troubleshooting and Solutions

- Check the Battery

Use a multimeter to check the battery voltage. If the voltage is below 12 volts, try charging the battery or replacing it. Also, make sure the battery terminals are clean and securely connected.

- Inspect the Starter Motor

Listen for any sounds from the starter motor when you try to start the truck. If there’s no response from the starter motor, check its internal brushes or consider replacing the starter motor.

- Inspect the Fuel System

Check that the fuel pump is functioning correctly when trying to start the truck. You can verify the fuel pressure to ensure it’s adequate. If the fuel pump isn’t working, it may need to be replaced or its electrical connections checked.

- Check the Ignition System

Inspect the ignition switch and spark plugs to ensure they are working properly. If the spark plugs are worn or damaged, replace them.

- Check Fuses and Relays

Inspect the fuses and relays that are connected to the starting system. If you find any blown fuses or faulty relays, replace them.

Conclusion

The issue of a C8500 truck not starting can be caused by several factors, such as a weak battery, a faulty starter motor, fuel system problems, or ignition system failure. By methodically troubleshooting and addressing each potential issue, you can effectively resolve the no-start problem and restore the vehicle to full working order.

|

|

|

| CAT 299C Hydraulic Oil Pre-Heat Issue Analysis |

|

Posted by: MikePhua - 07-07-2025, 12:31 AM - Forum: Operator Talking

- No Replies

|

|

Common Causes of Hydraulic Oil Pre-Heating

The hydraulic oil pre-heating issue on the CAT 299C skid steer loader is a common concern among users. According to feedback from various engineers and equipment technicians, there are several potential causes for hydraulic oil temperature issues. High hydraulic oil temperature can affect machine performance and may even lead to system failures.

Potential Factors Leading to High Temperatures

There are many factors that can contribute to high hydraulic oil temperatures, including internal leaks in the system, malfunctioning hydraulic pumps, and environmental factors such as extreme cold weather. In colder climates, the equipment may need to warm up before reaching optimal working temperatures. If the heating function of the system is faulty, the hydraulic oil temperature may not be properly regulated.

System Diagnostics and Troubleshooting

To effectively diagnose the hydraulic oil pre-heat issue, users should first check if the hydraulic oil temperature sensor is functioning properly. If the sensor fails, it may give false readings or fail to display accurate temperatures, causing the system to malfunction. Next, it's important to inspect the hydraulic pump's operation and look for any internal leaks that may cause abnormal oil pressure.

How to Handle High Hydraulic Oil Temperatures

If high hydraulic oil temperatures are confirmed, users should first check the quality and quantity of the hydraulic oil. Dirty or insufficient oil can affect the pump’s performance and lead to higher oil temperatures. When replacing hydraulic oil, make sure to use the brand and type recommended for the equipment. Additionally, it’s crucial to regularly replace oil filters to ensure the smooth functioning of the hydraulic system.

Conclusion

The hydraulic oil pre-heating issue on the CAT 299C skid steer loader can be addressed by troubleshooting the machine's operational status and conducting timely system checks and maintenance. Regular inspection of sensors, pumps, and hydraulic oil quality can effectively prevent overheating issues, ensuring optimal machine performance and extending its lifespan.

|

|

|

| Issue with the Stabilizer Self-Aligning Bushings on the 580C Backhoe |

|

Posted by: MikePhua - 07-07-2025, 12:31 AM - Forum: Operator Talking

- No Replies

|

|

Overview of the Problem

The stabilizer system on the 580C backhoe has experienced issues with its self-aligning bushings. This problem affects the stability of the machine, particularly during operations where the stabilizer's precision is crucial, leading to operational difficulties.

Function of the Bushings and the Issue

Self-aligning bushings play a critical role in the stabilizer system of the 580C backhoe. They help to align the stabilizer arms and ensure they stay properly positioned during operations. However, over time, the bushings can wear out or shift, causing the alignment to fail. When this happens, the stability of the backhoe can be compromised, making it difficult to provide adequate support, which can affect the quality of work.

Causes of Bushing Wear

There are several reasons for bushing wear. The most common cause is heavy usage, especially in high-load environments, where the bushings are subjected to significant pressure, leading to rapid wear. Additionally, a lack of maintenance and inspections over time can lead to aging or loss of lubrication in the bushings, accelerating the wear process.

Solutions

To address the issue with the self-aligning bushings on the 580C backhoe, the following measures are recommended:

- Regular Inspection and Maintenance: To ensure the bushings function properly, regular inspections of the stabilizer system should be conducted, particularly after heavy or high-load operations. This will help identify wear and prevent further damage.

- Replacing Worn Parts: If the bushings show significant wear, they should be replaced promptly. When replacing the bushings, it is essential to use the correct bushing model and ensure proper installation to avoid future issues.

- Proper Lubrication: Bushings require adequate lubrication to reduce friction and wear. During inspections, ensure the lubrication levels are sufficient, and add grease as necessary to maintain smooth operation.

Conclusion

The self-aligning bushing issue on the 580C backhoe stabilizer is a common maintenance concern, especially in high-load working conditions. Regular inspections, maintenance, and timely part replacements can help prevent bushing wear and stabilizer system failure, ensuring the backhoe remains stable and efficient during operations.

|

|

|

| JD 210 LE Issues with Brake Stop Light Flashing and Blowing Fuel Gauge Fuse |

|

Posted by: MikePhua - 07-07-2025, 12:11 AM - Forum: Operator Talking

- No Replies

|

|

John Deere 210 LE excavator owners have reported issues with the brake stop light flashing and the fuel gauge fuse blowing frequently. These problems can interfere with the normal operation of the machine and might indicate potential issues in the electrical or braking systems. This article discusses these common problems and their possible solutions.

1. Flashing Brake Stop Light Issue

The flashing brake light is usually caused by an electrical malfunction. Some common causes include: - Faulty Brake Switch: The brake switch may be malfunctioning or have a poor connection. If the brake switch is defective, it could cause the brake light to flash. Testing and replacing the brake switch could resolve the issue.

- Loose or Corroded Wiring: A loose or corroded electrical connection in the brake light circuit can result in an unstable signal and cause the brake light to flash. Inspect the wires and connectors for wear and corrosion.

- Battery Voltage Issues: If the battery voltage is unstable or too low, it can affect the electrical system and cause irregularities like a flashing brake light. Check the battery voltage to ensure it's stable.

2. Fuel Gauge Fuse Blowing

Frequent blowing of the fuel gauge fuse can be caused by a few issues:- Electrical Short Circuit: A short circuit in the fuel gauge wiring is a common cause of blown fuses. Inspect the wiring for any exposed wires or damaged connections that could cause a short.

- Faulty Fuel Sensor: A defective fuel sensor might cause excessive current flow, blowing the fuse. Check the fuel sensor for any internal short circuits or damage.

- Overloaded Circuit: If the fuel gauge circuit is overloaded, it could lead to blown fuses. Ensure that there are no additional electrical loads causing an overload in the circuit.

3. Solutions

Here are some potential solutions to address the issues:- Inspect the Brake Switch and Wiring: Test the brake switch to ensure it's functioning correctly. If the switch is defective, replace it. Also, check the brake light circuit for any loose connections or corrosion.

- Check Battery Voltage: Measure the battery voltage to ensure it is stable and within the correct range. Low or unstable battery voltage can affect the electrical system, including the brake lights and other electronic devices.

- Inspect for Short Circuits and Sensor Issues: Check the fuel gauge circuit for any short circuits and repair any damaged wiring. Also, inspect the fuel sensor to ensure it’s not defective or causing a short.

- Replace the Fuse: If the fuse blows, replace it with a new one of the correct rating. After replacing, check the circuit for any underlying issues that could cause the fuse to blow again.

Conclusion

The issues with flashing brake stop lights and blowing fuel gauge fuses in the JD 210 LE excavator are common electrical problems. These issues could be related to the brake switch, wiring connections, fuel sensor failure, short circuits, or battery voltage instability. By systematically checking each of these factors, you can pinpoint the source of the problem and take corrective actions to resolve it. Maintaining the electrical system of your excavator will help extend its lifespan and improve its overall performance.

|

|

|

|