The concept of using hydraulic power for more efficient digging in excavators began to take shape in the 1880s. One of the earliest attempts to incorporate hydraulic technology into excavation equipment was the 1882 excavator built by Sir W. G. Armstrong & Company in England. This machine was used in the construction of the Hull Docks. However, unlike modern excavators that use hydraulic fluid, this machine operated with water as the hydraulic fluid. Additionally, it was not a fully hydraulic machine, but a hybrid design that used cables to operate the bucket and a hydraulic cylinder to operate a set of multiplying sheaves. Unfortunately, this idea was not successful, and neither was a similar machine built in 1914 by Frank F. Armstrong for the Penn Iron Mining Company in the United States.

The First True Hydraulic Excavator: Kilgore's Innovation

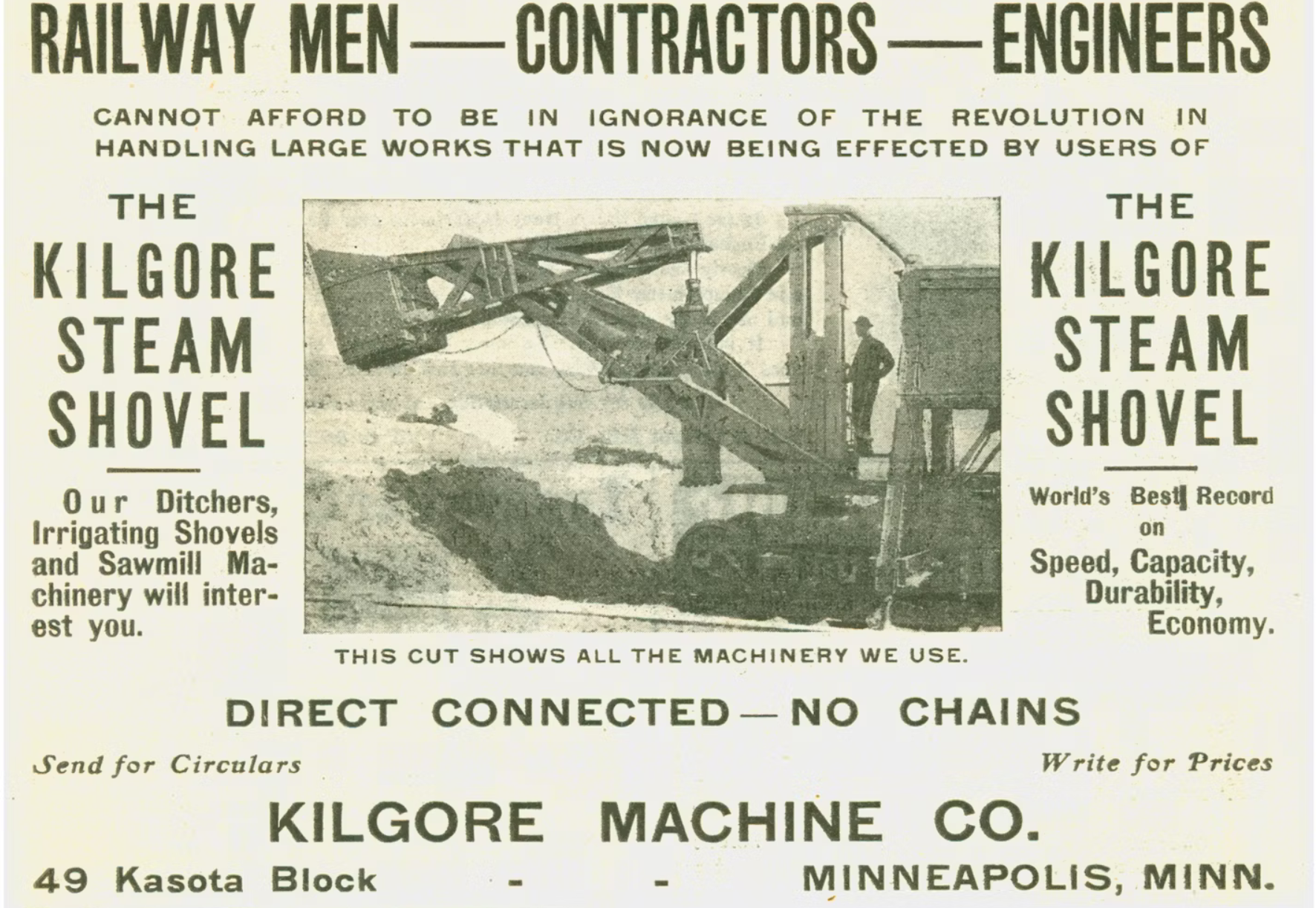

The first all-hydraulic excavator was created by the Kilgore Machine Company in 1897. This machine, called the Direct Acting Excavator, used four direct-acting steam cylinders for all bucket functions, eliminating the need for cables or chains, which were commonly used in conventional excavators at the time. This design marked a significant breakthrough in hydraulic excavation technology.

Kilgore’s design had several notable advantages:

Kilgore’s Direct Acting Excavator: Advanced Features

Kilgore’s Direct Acting Excavator was ahead of its time in many ways:

Kilgore’s Economic Advantage and Limited Success

Kilgore also marketed its machine’s economy of operation, noting that the cylinders required less steam, which translated into reduced fuel and water consumption compared to other traditional shovels. Moreover, the engineer operated all functions of the machine, eliminating the need for a second crew member to operate the dipper as in conventional machines.

Kilgore produced several railroad shovels with dipper capacities of 1-1/4 and 2-1/2 yards. They also created traction wheel shovels, steam ditchers for land reclamation and irrigation, and dipper dredges. Despite the advanced concepts, Kilgore’s Direct Acting Excavator met with limited success due to various factors, including competition from other established technologies and the limitations of the design at the time.

Conclusion

While Kilgore’s Direct Acting Excavator was a groundbreaking innovation in hydraulic technology, it did not achieve widespread commercial success. Nevertheless, it played an important role in the development of modern hydraulic excavators. The innovations introduced in this machine, such as cable-free operation, direct-acting cylinders, and more efficient energy use, laid the groundwork for future advancements in the field of excavation machinery.

The First True Hydraulic Excavator: Kilgore's Innovation

The first all-hydraulic excavator was created by the Kilgore Machine Company in 1897. This machine, called the Direct Acting Excavator, used four direct-acting steam cylinders for all bucket functions, eliminating the need for cables or chains, which were commonly used in conventional excavators at the time. This design marked a significant breakthrough in hydraulic excavation technology.

Kilgore’s design had several notable advantages:

- The excavator was made almost entirely of steel, making it robust and durable.

- All movements, including the full stroke of each cylinder, were cushioned, preventing shock or damage even when operating at high speeds and full stroke.

- The use of steam cylinders for all bucket functions provided a greater range of motion than typical cable-operated machines, allowing the bucket to crowd horizontally and manipulate larger obstacles such as boulders with greater ease.

Kilgore’s Direct Acting Excavator: Advanced Features

Kilgore’s Direct Acting Excavator was ahead of its time in many ways:

- The machine had equal power in all movements, allowing the bucket to be withdrawn under load without having to lift it to the top to clear the cut, a major advantage over conventional shovels.

- In the event the shovel derailed, the machine’s design allowed for the full application of power to lift it back onto the rails, a feature not seen in traditional machines.

- The dipper could be forcefully shaken with the cylinders to dislodge materials jammed inside, improving operational efficiency.

Kilgore’s Economic Advantage and Limited Success

Kilgore also marketed its machine’s economy of operation, noting that the cylinders required less steam, which translated into reduced fuel and water consumption compared to other traditional shovels. Moreover, the engineer operated all functions of the machine, eliminating the need for a second crew member to operate the dipper as in conventional machines.

Kilgore produced several railroad shovels with dipper capacities of 1-1/4 and 2-1/2 yards. They also created traction wheel shovels, steam ditchers for land reclamation and irrigation, and dipper dredges. Despite the advanced concepts, Kilgore’s Direct Acting Excavator met with limited success due to various factors, including competition from other established technologies and the limitations of the design at the time.

Conclusion

While Kilgore’s Direct Acting Excavator was a groundbreaking innovation in hydraulic technology, it did not achieve widespread commercial success. Nevertheless, it played an important role in the development of modern hydraulic excavators. The innovations introduced in this machine, such as cable-free operation, direct-acting cylinders, and more efficient energy use, laid the groundwork for future advancements in the field of excavation machinery.