| Welcome, Guest |

You have to register before you can post on our site.

|

| Online Users |

There are currently 244 online users.

» 0 Member(s) | 233 Guest(s)

Ahrefs, Amazon, Baidu, Bing, Claude, DuckDuckGo, Facebook, OpenAI, Semrush, Seznam, Sogou

|

|

|

| Can You Trust Excavator Hour Meters? The Hidden Trick You Didn’t Know About |

|

Posted by: MikePhua - 06-30-2025, 12:07 AM - Forum: Troubleshooting & Diagnosing

- No Replies

|

|

In the construction industry, the income of many equipment operators is based on the number of operating hours recorded by the machine's hour meter. However, some individuals have found ways to manipulate the hour meter, inflating the displayed hours to earn more money.

There are two primary methods used to alter the operating hours of excavators: one involves replacing the original hour meter with a special one, and the other involves installing a "time increaser" to interfere with the system’s signals. Here’s how they work:

1. Replacing the Hour Meter with a Special One

This method is relatively low-cost and simple. The special hour meters are designed to look almost identical to the original meters, and they can record time independently from the excavator’s main timing system. This allows users to adjust the displayed hours at will. By swapping out the original meter with one of these modified meters, it becomes easy to deceive site managers and make the machine appear to have more operating hours than it actually has. These modified hour meters are relatively inexpensive, typically ranging from a few dozen to a couple of hundred yuan each.

2. Installing a “Time Increaser”

This method is more sophisticated. It involves installing a device called a “time increaser,” which is connected to the engine's RPM signal circuit. This device sends a false signal to the system, making it believe that the engine is running even when it's not. As a result, the hour meter continues to accumulate hours whenever the excavator is powered on, even if the engine is not started. This method is more expensive, with prices typically ranging around a thousand yuan.

The Impact on the Industry

Manipulating hour meters to falsely inflate operating hours is, at its core, fraudulent behavior. It disrupts the normal order of the industry, undermining fairness and causing legitimate businesses to suffer. Due to weak regulation and low detection rates, this practice has been allowed to proliferate, becoming an open secret in the industry. If this continues, it will result in a situation where "bad money drives out good," leading to a loss of trust in the market and damaging the interests of all professionals in the field.

The Need for Integrity in the Industry

Maintaining a fair and healthy market environment requires the joint effort of everyone in the industry. Each individual should adhere to good professional ethics, conduct their business with integrity, and work together to resist such dishonest practices. Only by upholding a culture of integrity can the industry grow in a healthy and orderly manner, ensuring that all participants enjoy a fair and transparent working environment.

|

|

|

| Uncovering the Hidden Truth of Hour Meter Tampering in Used Excavators |

|

Posted by: MikePhua - 06-30-2025, 12:04 AM - Forum: Troubleshooting & Diagnosing

- No Replies

|

|

In the second-hand excavator market, one of the most prevalent and concerning practices is the tampering of hour meters. The lack of regulation in the second-hand machinery trade, coupled with the low cost of tampering, has led to a vicious cycle, eroding trust in hour readings and making it difficult for buyers to trust the accuracy of these meters.

Two Types of Hour Meters

Currently, there are two types of hour meters on the market:

- Mechanical Meters: Found mostly on older models and domestic brand excavators. These can be easily tampered with by physically adjusting the meter.

- Digital Meters: Newer excavators generally use digital hour meters, which are more complex and require special software to hack and modify the data.

The Rise of an Industry: Hacking Hour Meters

The practice of hacking hour meters has become a lucrative industry. Specialized services now exist to modify these meters for a fee. Through extensive investigation, we were able to uncover the methods used by these individuals to manipulate the data.

How the Tampering Works

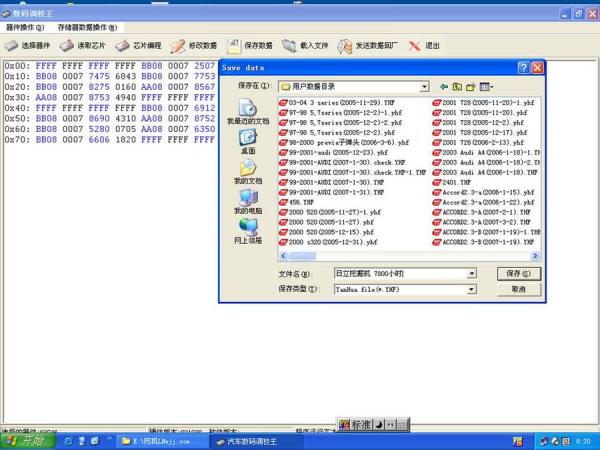

To understand how the tampering works, we need to look at the principles behind the digital hour meter:- The time data is stored in an encrypted format within the digital meter’s computer board. By identifying the data storage location and using specialized software to modify the chip parameters, the time display can be adjusted to show any desired number of hours. While the exact methods may vary depending on the excavator brand and model, the process is generally the same.

The Process of Modifying the Hour Meter

Here’s the basic process for tampering with an hour meter:

- Remove the Chip and Identify the Model

The first step is to disassemble the computer board, extract the circuit board, and locate the chip that stores the time data. Professionals who specialize in this know exactly where to find the chip and how to identify its model quickly.

- Locate the Data Storage on the Chip

Using specialized programming software, the data stored on the chip can be read and modified. All it takes is connecting the chip and opening the software.

- Read and Save the Data

Once the data is accessed, it is saved in a separate file for future reference.

- Modify the Data

The data is then adjusted to show the desired number of hours. Once the chip is reinstalled into the computer board and the excavator is powered on, the hour meter will display the modified value. This entire process can be completed in just 10 to 15 minutes by a skilled technician. For example, a 20,000-hour machine can easily be modified to appear as though it has only 2,000 hours.

The Dark Side of the Used Machinery Market

The practice of tampering with hour meters is just one of many issues plaguing the used construction machinery industry. It reveals a deeper societal problem regarding integrity. Initially, a few dishonest sellers exploited this practice to make quick profits, disturbing the fairness of the market. Over time, however, even the honest sellers felt forced to engage in tampering just to remain competitive, leading to the creation of an underground industry dedicated to modifying hour meters. There are now even paid courses teaching people how to adjust hour meters.

An Ongoing Struggle for Integrity

While it may be difficult for any one entity to fully reform the industry and eliminate these dishonest practices, the push for progress remains crucial. Even though it’s an uphill battle, the goal is to promote integrity and transparency within the used equipment sector, ensuring a healthier, more trustworthy marketplace for all.

|

|

|

| Transmission Air Circuit Failures and Solutions |

|

Posted by: MikePhua - 06-29-2025, 11:59 PM - Forum: Troubleshooting & Diagnosing

- No Replies

|

|

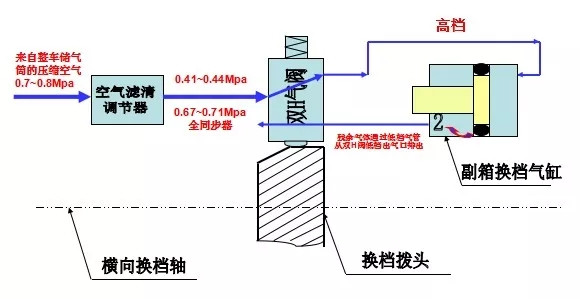

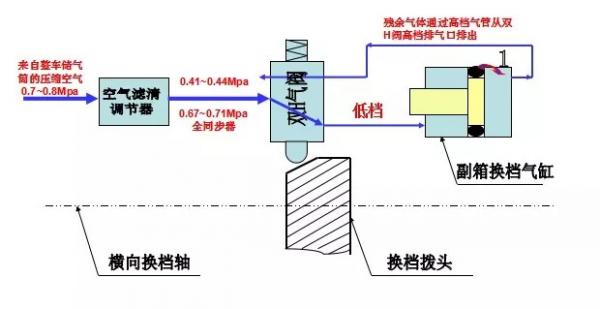

The Fast Transmission is widely used in SANY’s heavy equipment, with its distinctive main and auxiliary box, dual intermediate shaft structure, and air-operated control system leaving a strong impression on users. However, properly handling air circuit failures, especially those related to the dual-H valve, can be quite challenging.

Failure Symptoms and Root Cause Analysis

When the transmission selects a low gear, compressed air passes through the low gear exhaust port of the dual-H valve and enters the low gear intake of the auxiliary shift cylinder, pushing the piston to the right. During this process, residual air in the cylinder is expelled through the high gear exhaust port of the dual-H valve, which typically produces a brief exhaust sound. This is normal. However, if the exhaust persists for too long, it can affect gear shifting, becoming a failure symptom.

It's important to note that air leakage in the dual-H valve is not due to the valve’s quality, but rather the result of poor sealing in the auxiliary shift cylinder, which causes air leakage and is reflected in the dual-H valve.

When the transmission selects a high gear, compressed air enters the high gear intake of the auxiliary shift cylinder through the high gear exhaust port of the dual-H valve, pushing the piston to the left. As this happens, residual air is expelled through the low gear port. This process also produces a short exhaust sound, but if the exhaust persists for too long, it can similarly disrupt gear shifting.

Sealing Issues and High-Low Gear Shifting Problems

The auxiliary shift cylinder uses three sealing rings to maintain a relatively sealed environment. However, as wear and tear accumulate over time, the sealing environment of the cylinder can be compromised. This leads to delays or failure to shift properly when changing between low and high gears.

In many repair situations, technicians may assume that air leakage from the dual-H valve requires a replacement of the valve itself. While changing the valve may temporarily resolve shifting issues, it does not address the root cause. The increased air pressure from a new dual-H valve may temporarily enhance the piston’s pushing force, superficially solving the gear shifting problem. However, the sealing environment of the cylinder remains unaddressed, and the issue will resurface shortly. This could lead to further damage, such as the wear or burning of the auxiliary shift cylinder.

Correct Repair Method

To properly address the issue of high-low gear shifting difficulty, the first step should be to check the sealing of the auxiliary shift cylinder. Replace any failed sealing rings or repair the damaged cylinder body to restore a proper seal. Only then should other air circuit components be considered for replacement to ensure an accurate and effective resolution.

In conclusion, correctly diagnosing the root cause of air circuit failures and focusing repairs on the sealing of the auxiliary shift cylinder will help avoid recurring failures from temporary fixes, ensuring long-term reliability and stable operation of the equipment.

|

|

|

| Kobelco SK210LC-8 Excavator Review: In-Depth Performance Analysis |

|

Posted by: MikePhua - 06-29-2025, 10:41 PM - Forum: General Discussion

- No Replies

|

|

The Kobelco SK210LC-8 hydraulic excavator is one of the company's flagship models in the Chinese market, consistently ranking among the top-selling 21-ton excavators. Recently, a seasoned user shared a detailed review of the SK210LC-8 based on their experience, providing an insightful look into the machine's performance and capabilities. Let’s take a closer look at what makes this excavator stand out.

The "Green Arrow" of Excavators

The Kobelco SK210LC-8 features a distinctive green paint job, reminiscent of the superhero "Green Arrow." The color evokes a sense of power and reliability, making it a unique and striking machine on any construction site.

Kobelco, also known as Kobe Steel, is one of Japan’s major industrial manufacturers and a recognized name in the construction machinery sector. While it may sit in the middle of the rankings compared to other heavyweights like Caterpillar, Komatsu, and Hitachi, Kobelco’s excavators have a strong following, thanks to their competitive pricing and solid reputation for quality.

Key Differences: SK200-8 vs SK210LC-8

The Kobelco SK210LC-8 differs from its predecessor, the SK200-8, in several key areas:

- Bucket Capacity: The SK200-8 comes with a smaller 0.8m³ bucket, while the SK210LC-8 is equipped with a 1.0m³ bucket. This larger bucket increases efficiency, especially in tougher working conditions, although it may struggle with compacted soil compared to smaller models.

- Track and Idler: The SK210LC-8 features an extended track and an additional idler wheel (8 wheels in total), making it more stable and better suited for demanding tasks.

- Fuel Consumption and Efficiency: While the SK210LC-8 offers higher operational efficiency, it comes at the cost of increased fuel consumption compared to the SK200-8. This difference is particularly noticeable when working in areas where the load is lighter, but for heavier projects, the SK210LC-8’s superior performance makes it the preferred choice.

Comparison with Komatsu PC200-8

When comparing the Kobelco SK200-8 with Komatsu's PC200-8, several aspects stand out:

- Engine Power: The Komatsu PC200-8 uses a 6-cylinder engine, while the SK200-8 uses a 4-cylinder engine. The Komatsu’s engine provides more power, especially when working in tougher soil, but the SK200-8 excels in fuel efficiency, saving up to 20-30% in fuel costs per hour.

- Bucket Size: The SK200-8's larger bucket makes it easier to load loose soil, and its better weight distribution and faster rotation give it an edge in loading operations on similar-sized platforms.

- Durability and Maintenance: Although Komatsu's market share is higher and its after-sales service is more robust, the Kobelco SK200-8 has proven to be quite durable in its own right. However, Komatsu’s equipment tends to hold its value better, making it a safer choice for long-term investment.

Real-World Experience with the SK210LC-8

The SK210LC-8 under review was purchased in April 2010 for ¥980,000, with the total cost rising to ¥1,140,000 after financing. Over the course of 4 years, it has worked for 6,480 hours, mostly on earthworks, loading, and site leveling. After the initial maintenance period, the machine’s parts and maintenance were handled by Kobelco’s after-sales service team.

The operator reported that the machine had no major issues through its first 6,000 hours, with the engine and hydraulic system running smoothly. However, at around 6,000 hours, some leakage issues were observed with the hydraulic valves, and some minor hydraulic fluid leaks were found in the joystick and swing motor. Despite several repair attempts, the issue remains, although it doesn’t significantly affect the machine's performance.

Fuel Consumption and Operating Costs

For its class, the SK210LC-8 has an average fuel consumption of 120-130 RMB per hour, with an operating cost of around 260 RMB per hour for general work. While fuel consumption is higher than some smaller machines, the SK210LC-8’s efficiency in more demanding tasks justifies the extra cost.

Conclusion: Is the SK210LC-8 Right for You?

The Kobelco SK210LC-8 is a reliable and high-performance excavator suitable for heavy-duty tasks, offering a good balance of power and fuel efficiency. It’s particularly favored for its speed and agility, making it ideal for those who require quick and effective results on the job site.

While it may not offer the same level of durability as some high-end brands like Komatsu, it stands out in terms of cost-effectiveness and overall operational value. If you’re looking for a machine that provides a great mix of speed, performance, and value, the SK210LC-8 is a strong contender in the 20-21 ton category.

If your work involves heavy digging or harsh environments, the Kobelco SK210LC-8 could be a solid investment, especially if you’re working within a set budget and require a machine that can deliver consistent results.

|

|

|

| Hyundai R60-9 Excavator Review: 6500 Hours of Use and Performance Evaluation |

|

Posted by: MikePhua - 06-29-2025, 10:40 PM - Forum: General Discussion

- No Replies

|

|

The Hyundai R60-9 is a popular small excavator in the market, known for its stable performance and high cost-effectiveness. Recently, a senior user shared their experiences and evaluations of the Hyundai R60-9 after 6500 hours of usage. Here's a detailed breakdown of the machine’s features, performance, and long-term usability.

Model Overview

Hyundai Heavy Industries, a subsidiary of the Hyundai Group, is known for manufacturing high-quality construction machinery. The Hyundai R60-9 is part of the company’s -9 series, launched in 2011, and positioned as a small to medium-sized excavator. The new machine was priced at ¥350,000, but with a national agricultural subsidy of ¥40,000, it only cost ¥310,000, along with ¥5,000 worth of accessories.

Key Differences Between R60-9 and Previous Model (R60-7)

The R60-9 made several improvements over its predecessor, the R60-7:

- Fuel Tank & Bucket Capacity: The fuel tank capacity was increased, and the bucket size was expanded, but the overall weight of the machine was reduced. It also features an automatic throttle system for better control.

- Cab and Console Design: The R60-9 boasts a more streamlined and simplified instrument panel, improved switch layout, and an added rearview mirror. The rear-view mirrors are adjustable, offering multiple angles for better visibility.

- Hydraulic System & Cooling: The R60-9 uses a high-quality hydraulic pump imported from Japan, which improves hydraulic system reliability and durability. The cooling system was also enhanced with an added oil cooler and an aluminum radiator, which helps with better heat resistance.

Exterior and Interior Design

The Hyundai R60-9 continues the traditional yellow and black color scheme of Hyundai’s excavators. One standout feature is the rear-hinged cab design, which provides more space inside. The rearview mirrors are foldable and adjustable to help improve visibility during operations in tight spaces. The cab is also ergonomically designed with easy-to-operate controls, making the machine comfortable for long working hours.

Despite the thoughtful design, there are some drawbacks in terms of air circulation within the cab. During hot weather, the cooling performance of the air conditioning system is not as efficient, leading to discomfort for the operator.

Performance

The R60-9 is designed for light to medium-duty tasks, commonly used for landscaping, pipeline installation, and small construction jobs. The bucket capacity is 0.24 cubic meters, and it can be expanded through basic welding to handle more material. The engine is powered by a Yanmar 4TNV94L direct injection diesel engine, providing sufficient power for small-scale operations.

The hydraulic system, using an imported Japanese hydraulic pump, ensures smooth and coordinated operation, which is a key advantage for precision tasks. However, during heavy-duty operations, such as digging through tough soil or lifting heavy objects, the operator noted that the machine’s power might feel slightly underwhelming.

After 6500 hours of use, the machine has shown consistent performance, with only minor issues such as oil leaks from hydraulic pipes and a few replacements of seals. The most significant repairs were related to the arm, which had to be welded after cracking due to prolonged high-intensity work. The engine’s water tank required sealing at 5500 hours, and the motor’s internal bearings were replaced at 5500 hours, costing around ¥1,000.

Maintenance and Parts

The user generally opts for affordable aftermarket parts like bucket teeth, filters, and oils after the original parts are used up. The machine’s maintenance costs are relatively low, but there’s a concern with the rubber tracks. Unlike competitors like Komatsu, the tracks on the R60-9 do not have perforated areas for easy attachment and require bolts on both sides, making them less stable and prone to issues such as detachment.

Cost Performance

The Hyundai R60-9 offers great value for its price. It is considerably more affordable compared to other imported brands, yet still delivers good performance for most standard tasks. The machine’s fuel consumption is reasonable at around ¥25 per hour, and it is very cost-effective in comparison to other models in the same price range.

From the perspective of the owner, the machine’s price is reasonable for its reliability and efficiency. Even after years of use, the R60-9 retains its value and can be sold for around ¥150,000. Compared to other similar machines, its affordable price and lower maintenance costs make it a great option for budget-conscious users.

Conclusion

The Hyundai R60-9 is a reliable and cost-effective small excavator, offering good performance for various light to medium-duty tasks. While its performance may not match high-end imported machines in terms of power, it compensates with lower maintenance costs, good fuel efficiency, and an affordable price point. This makes the Hyundai R60-9 a great choice for users seeking a durable and practical machine without breaking the bank.

|

|

|

| A Closer Look at the Features of the XCMG RP601L Wheel Paver |

|

Posted by: MikePhua - 06-29-2025, 10:36 PM - Forum: General Discussion

- No Replies

|

|

In this interview, we spoke with two operators who have 5-6 years of experience operating a XCMG RP601L Wheel Paver. They primarily use the machine for laying asphalt concrete surfaces. This type of wheel paver is well-suited for small to medium-sized municipal projects that require quick paving and fast job site transitions. Below is an overview of their feedback and the machine's performance.

Background of the Owner

Owner: Yu Lixin

Yu Lixin is a private road construction contractor based in Beijing. He owns over 20 pavers, including 7 Volvo ABG series pavers and several XCMG models. In addition to pavers, Yu Lixin also operates 6 large Wirtgen milling machines, more than 10 small Wirtgen milling machines, and dozens of rollers of various tonnages. His extensive fleet reflects his substantial presence in the road construction industry.

Purchase Details

The operators could not recall the exact year the XCMG RP601L paver was purchased, and due to the machine's age, its nameplate has been lost. However, they confirmed that they have been using this paver for 5 to 6 years, making it an older model.

Operator Background

The two operators, both born in the 1980s, have a great deal of experience with this particular paver. They have maintained and operated it for several years, and their daily upkeep and maintenance practices are one of the reasons why the machine continues to function well.

Working Conditions

The XCMG RP601L is mainly used for small projects such as playgrounds, residential areas, and road repairs. These projects require quick work and frequent transitions. The machine has worked a total of approximately 3,500 hours (as per the display) since it was purchased.

Efficiency in Operation

The XCMG RP601L's small size and hydraulic extendable screed contribute to its high operational efficiency and quick job transitions. The hydraulic extendable screed allows for stepless adjustments to the track width, making it ideal for small, dynamic work environments. Over the past 5-6 years, the machine has only required short-term downtime for routine maintenance and the replacement of the screed's wear materials. There have been no major breakdowns during its operation.

Product Performance and Issues - Engine:

The paver is equipped with a Shangchai D4114 turbocharged direct injection diesel engine, which delivers a maximum output power of 100kW. The engine has remained reliable throughout the years, with no major issues reported except for regular maintenance.

- Hydraulic System:

The operators have not encountered any failures that caused the machine to stop working due to the hydraulic system. However, minor issues such as oil leakage or seepage from the oil pipes have occurred intermittently.

- Steering System:

One notable issue with the XCMG RP601L is the small wheel steering system. During steering, the machine’s wheels are prone to slipping, especially when the turning radius is tight. This requires the operators to make multiple steering adjustments, which can reduce the machine’s overall efficiency.

After-Sales Service and Spare Parts

Given that the owner has a large fleet of road equipment and an in-house maintenance shop, most repairs and maintenance tasks are handled internally. The operators are responsible for daily upkeep and are not in frequent contact with the dealership’s after-sales service team. Spare parts, including routine maintenance items, are purchased in bulk by the company, so the operators are not aware of the exact cost of each maintenance session.

Fuel Management

When the paver is working on-site, there are two main fuel management scenarios:

- Small Projects, Return on the Same Day: The machine’s fuel tank is filled up using the company’s refueling truck before leaving for the job site.

- Large Projects, Extended Time Away: When the machine cannot return the same day, the fuel tank is filled before departure, and a backup fuel tank is also filled to ensure the machine can run throughout the project.

Conclusion

The two operators have worked with this XCMG RP601L Wheel Paver for several years and consider it durable and reliable. They describe the machine as "tough and reliable—no major issues, just small ones from time to time." While the XCMG RP601L may not have the same stability and performance as some foreign-brand pavers, its lower price point, ease of maintenance, and lower operating costs make it an attractive option for cost-conscious customers.

We hope this interview provides useful insights for those considering purchasing a paver. Feel free to share your thoughts and suggestions in the comments section.

|

|

|

| The Future of Excavators: What Might They Look Like? |

|

Posted by: MikePhua - 06-29-2025, 10:33 PM - Forum: General Discussion

- No Replies

|

|

Recently, a forum discussion titled "Ultimate Customization: What Additional Features Would You Like to See on the Caterpillar 320D2 Excavator?" sparked enthusiastic participation among machine operators and owners. This discussion allowed participants to share their ideas and suggestions for improving excavator designs, many of which were not only creative but also highly practical. Here's a summary of the most interesting ideas and suggestions that emerged from this event.

1. Mobile Phone Holder

Suggestion by: [Crazy Excavator]

In today’s world, smartphones are essential, especially for machine operators who need to stay connected while on the job. One of the most requested features was a mobile phone holder installed on the operator’s side of the cabin. Not only would this allow for easy access to make or receive calls, but it could also function like a dashcam, enabling operators to record videos of their work for training or sharing experiences with other operators.

2. Excavator Anti-Theft Lock

Suggestion by: [Xiao Zhuang Zhuang]

The issue of theft is a serious concern in construction areas, especially given how vulnerable excavators are when left unattended. Much like the anti-theft systems in cars, it was suggested that excavators be equipped with a GPS-based anti-theft alarm system. This system would alert the operator or owner via their mobile phone in case of unauthorized tampering or movement. Additionally, a reinforced protective shell for the control panel was recommended to further secure valuable components.

3. USB Charging Port, Onboard Refrigerator, and Extra Seat

Suggestion by: [Gemstone Engineering Vehicle]

For operators who spend long hours in the cab, comfort and practicality are key. Several suggestions were made to enhance the operator’s experience: - Onboard Refrigerator: Especially during hot weather, an onboard mini-fridge could provide chilled beverages to keep operators refreshed.

- Radio and Speaker: For long days on the job, having access to music or news would help combat fatigue. A simple radio or speaker system could make the time spent in the cab more enjoyable.

- USB Charging Port: Modern smartphones consume a lot of power, and a USB charging port would ensure the operator’s device stays charged throughout the day.

- Additional Seat: Many operators and business owners work with apprentices or assistants, and an extra small seat behind the main driver’s seat would be a perfect addition for better team coordination.

4. Loudspeaker System

Suggestion by: [Gemstone Engineering Vehicle]

Installing a loudspeaker system could eliminate the need for operators to shout across noisy job sites. This would save time and reduce physical strain, as the operator could communicate clearly with nearby workers without leaving the machine.

5. Fall Prevention Handrails

Suggestion by: [Overseas Excavator Manufacturer]

In some foreign markets, excavators are equipped with fall prevention handrails, particularly around the engine hood. These handrails provide safety for operators who may need to access the top of the machine for maintenance or inspection, reducing the risk of falls.

Editor’s Comments- Power Supply: Manufacturers should consider including multiple voltage output ports and sufficient energy reserves in the design, allowing operators to install additional electronic devices easily.

- DIY Modifications: Many of the suggested modifications, such as the mobile phone holder, anti-theft lock, and additional seat, can be achieved by purchasing existing products and making simple modifications on your own. Operators may want to try these ideas out for themselves.

- Emerging Market for Excavator Customization: Customizing excavators is becoming an emerging trend. While manufacturers typically won’t offer these types of modifications, specialized aftermarket providers could cater to a growing market. With the right expertise, operators-turned-customizers could create a profitable niche business, especially in regions with a high concentration of excavators.

Looking Toward the Future

Years ago, a group of American students buried a time capsule filled with predictions about the future. Many of their forecasts, such as space travel and inflation, have come to fruition. Similarly, the ideas shared in this forum, though they may seem far-fetched today, could soon become reality.

As the market for excavators becomes increasingly competitive, manufacturers that focus on improving comfort, automation, and additional features will likely gain a loyal following. It’s clear that the future of excavators will not only be about performance but also about making the operator’s experience more enjoyable, efficient, and safe.

|

|

|

| User Experience with the Joint Venture Hitachi ZX250H-3G Excavator |

|

Posted by: MikePhua - 06-29-2025, 10:30 PM - Forum: General Discussion

- No Replies

|

|

Recently, we interviewed an operator in Changping District, Beijing, who has been using the joint venture Hitachi ZX250H-3G excavator for the past three years, with a total of 4300 hours of operation. Let's explore his experience and how this excavator performs in various work conditions.

Purchase Information

The operator's employer is from Shandong, and the Hitachi ZX250H-3G was purchased through financing in 2010 from Beijing Junma. The financing period is three years, with a total price of 1.3 million RMB, and the excavator has been in operation for 4300 hours. The loan has not yet been fully repaid.

Over the years, the employer has owned various brands of excavators, including two Shinsei 240 large excavators, a Doosan 225 excavator, and a Komatsu PC56 small excavator. While the loans for the previous excavators have been paid off and are currently profitable, the loan for the Hitachi ZX250H-3G remains outstanding.

When asked why the employer has purchased a mix of brands, the operator explained that it was due to fluctuating working capital. When funds were sufficient, the employer would opt for higher-priced brands, while more cost-effective brands were purchased during leaner times. For example, the Doosan 225 was purchased under such circumstances.

Operator Information

The operator, Wang, is from Zhangjiakou, Hebei, and is in his 30s. He has been working with his employer for many years and has extensive experience operating different brands of excavators, including the Shinsei, Doosan, and Komatsu machines.

Equipment Condition and Work Environment

Since its purchase in 2010, the Hitachi ZX250H-3G has run for 4300 hours. The majority of the work involves various small tasks such as trenching, land leveling, pipe laying, and landscaping. The machine has also been used on a few mining sites and for occasional crushing work. However, it has mostly handled short-term projects with minimal heavy-load operations. Wang is diligent about maintenance, so the excavator looks almost new.

The equipment is used for jobs like: - Earthmoving work: 1200 RMB per day

- Crushing work: 1800 RMB per day

- Crushing work (self-fueled): 3500 RMB per day

Work Efficiency and Fuel Consumption

When compared to the Shinsei excavators Wang has operated in the past, the Hitachi ZX250H-3G's speed is slightly slower, particularly in rotation and digging movements. However, Wang is quite satisfied with the excavator's digging power, especially when working with tough soil. The H-version mining arm provides ample power for earthmoving tasks.

Regarding fuel consumption:- The average fuel consumption for a full-day job is approximately 900 RMB.

- If the job site provides fuel, the operator increases the throttle to around 8 levels (out of 10) for better efficiency.

- When using personal fuel for the job, the throttle is lowered to about 5 levels to save costs while maintaining a slower, more precise pace.

The fuel is sourced from various providers, including Sinopec and PetroChina, as well as on-site suppliers. Thankfully, the direct-injection system on the ZX250H-3G has not experienced any fuel-related issues.

Product Performance and Issues

- Engine:

The Hitachi ZX250H-3G is equipped with the Isuzu AA-6BG1T direct-injection engine. It provides sufficient power and has operated smoothly without any overheating issues.

- Hydraulic System:

The hydraulic system has proven to be stable, with no major faults affecting work performance. The walking mechanism is powerful, but the rotational bearing has a slight gap in design, leading to less smooth and stable rotation.

- Work Equipment:

Overall, the work equipment is very sturdy and has been capable of handling various projects, including tough soil excavation.

- Other Components:

The alternator belt was recently replaced after it snapped during operation. Fortunately, the issue was detected in time, and a new belt was installed at a minimal cost.

After-Sales Service

Wang is not completely satisfied with the after-sales service from the dealer. When calling for assistance, the response time is usually one to two days. However, after the warranty expired, Wang has had little interaction with the dealer except for paying the remaining loan installments.

Parts and Maintenance

After the warranty period, the employer stopped purchasing original parts from the dealer to save costs. Instead, cheaper third-party parts are sourced from the parts market, especially for the air filter, engine oil filter, and fuel filter. Wang mentioned that despite using non-original parts, there has been no noticeable difference in performance. Maintenance intervals are slightly adjusted, with the operator performing maintenance a few hours earlier than the recommended schedule.

Summary

Wang's experience with the Hitachi ZX250H-3G highlights the excavator's stability and adaptability for various work conditions. Although it has a few minor issues such as the hydraulic oil pipe leakage and rotational smoothness, its overall performance is reliable, especially when dealing with tough soil and earthmoving tasks.

For those looking to invest in an excavator, the Hitachi ZX250H-3G stands out for its strong digging power and fuel efficiency. With proper maintenance and a mindful approach to operating costs, this excavator can be a solid investment for small to medium-scale projects.

Wang also noted that, like many other machine owners, his employer is facing challenges with recovering payments for completed projects. Despite this, Wang remains optimistic, acknowledging the financial pressure on the employer and hoping for smoother cash flow in the future.

|

|

|

| Real-World Use of the Hyundai R60-7 Excavator After 4,731 Hours |

|

Posted by: MikePhua - 06-29-2025, 10:25 PM - Forum: General Discussion

- No Replies

|

|

We recently spoke with a Hyundai R60-7 excavator owner, who has used the machine for 4,731 hours. In this article, we’ll share his insights into the machine's performance and how it has helped with his business operations.

Purchase Details

The owner of the Hyundai R60-7, Mr. Zhang, is from Xingtai, Hebei Province, and has been in the construction machinery industry for over six years. He has operated several excavators, including a Sunward SWE50 mini excavator, two used Komatsu PC56-7 machines, a Doosan DH150-7 wheeled excavator, and currently, the Hyundai R60-7.

In 2007, Zhang purchased the Sunward SWE50 for 270,000 RMB. Over the years, the machine had some minor issues, especially with the hydraulic oil pipes that showed signs of wear, and during hot summer months, he couldn’t use the air conditioning due to engine overheating. He sold it for 70,000 RMB last year.

After the Sunward machine, Zhang bought two used Komatsu PC56-7 excavators, both with 5,000 to 6,000 operating hours, at a price slightly above 200,000 RMB each (new cost: 360,000 RMB). He is still using the Komatsu machines and finds their performance satisfactory.

In 2011, Zhang bought his Hyundai R60-7 for 300,000 RMB. The dealer was Beijing Ruizhidao Engineering Machinery Equipment Co., Ltd. He was drawn to Hyundai’s reputation for retaining value and made the purchase largely based on this feedback from friends.

Driver and Staff Details

Zhang employs two drivers: his son and a fellow villager. Both drivers are relatively young, and their salary is around 3,500 RMB per month (with 2 years of experience). Zhang provides food and lodging for his drivers, but with the growing business, he's planning to hire another full-time driver in the near future.

Equipment Usage and Work Conditions

Since purchasing the Hyundai R60-7 in 2011, it has accumulated 4,731 working hours. The machine mainly works on small local projects, including trench digging, land leveling, pipe installation, and landscaping. Although the machine comes equipped with a hydraulic breaker, it is rarely used and only comes into play when the ground is particularly hard.

Compared to the Komatsu PC56-7, Zhang notes that the Hyundai R60-7 is slightly slower but offers more power, which is especially noticeable when digging frozen soil in the winter months.

In Beijing, the going rate for 60-ton mini-excavators is approximately 800 RMB per day for regular work and 1,600 RMB per day with a breaker. After accounting for fuel and maintenance costs, Zhang sees a reasonable profit, bolstered by the work from his other two excavators, including the Komatsu machines and the Doosan DH150-7.

Work Efficiency and Fuel Consumption

Zhang is satisfied with the work efficiency of his Hyundai R60-7. The machine performs with balanced speed, moderate swing speeds, smooth movements, and high digging power.

The fuel consumption for the Hyundai R60-7 is about 180 RMB per workday. When working at full load, the fuel cost rises above 200 RMB, and the fuel tank (120L capacity) needs to be refilled every 3-4 days. This consumption is average for a machine of its size.

Performance and Issues

- Engine:

The Hyundai R60-7 is powered by a 39.5 kW Yanmar 4TNV94L engine. Zhang finds the engine to be both powerful and stable, with low noise levels. So far, the engine has not experienced any failures.

- Hydraulic System:

Zhang did encounter an issue with the hydraulic pipes. Three output hoses from the main pump developed leaks while still under warranty. After the dealer replaced the hoses, the problem persisted. Zhang then sourced new hydraulic hoses from a local repair shop, which solved the issue. These new hoses, totaling 1.8 meters in length, cost him only 175 RMB.

- Other Issues:

Zhang was particularly impressed with the air conditioning system of the Hyundai R60-7, which performs excellently in both heating and cooling. However, he reported that the horn had recently stopped working and was planning to fix it himself.

After-Sales Service

While there was a delay in resolving the hydraulic hose issue, Zhang is generally satisfied with the service from Beijing Ruizhidao. The response time for service requests ranges from 2 hours to half a working day, depending on proximity.

Parts and Maintenance

Beijing Ruizhidao offers free maintenance for the first two years or 3,000 hours, whichever comes first. After this, Zhang will be charged for labor. For now, Zhang is satisfied with the cost of parts, as the machine uses Hyundai-specific hydraulic oil, and each maintenance session consumes around 70 liters of oil (split across four 18-liter barrels).

Conclusion

Zhang’s experience with the Hyundai R60-7 after 4,731 hours of operation is a testament to the machine's reliability and strong performance. Although minor issues like hydraulic leaks arose, they were quickly addressed, and overall, the machine has met Zhang’s expectations for power, comfort, and efficiency. His feedback provides valuable insights for others looking to purchase a mini-excavator.

|

|

|

| Why the Hebei Owner Purchased Two CAT 306E Excavators |

|

Posted by: MikePhua - 06-29-2025, 10:24 PM - Forum: General Discussion

- No Replies

|

|

Li, a construction equipment owner from Xianghe County, Langfang City, Hebei Province, made headlines last year when he bought a CAT 306E mini-excavator. Now, just six months later, he's purchased a second one. What prompted this decision? Let's take a look at his experience and how these machines are performing in his daily operations.

Purchasing the Machines

Li's first CAT 306E was purchased outright, which meant no monthly payment burden. Satisfied with the performance of the first unit, he decided to expand his operations by buying a second one. A salesperson from the Beijing branch of the dealer offered Li a demo model with under 80 working hours, lightly used on the company's site for customer testing. The machine was available at a discounted price, and Li secured a bank loan to purchase it for 360,000 RMB. With monthly payments of only around 2,000 RMB, Li found the financial pressure manageable.

Driver Situation

When Li only had one machine, he operated it himself. However, as his fleet grew, the workload increased. With many construction projects nearing completion at the end of the year, there were fewer jobs available. For the time being, Li hired a temporary driver at 300 RMB per day. Li plans to recruit a permanent driver in the new year, with salaries in the local Langfang area ranging from 4,000 to 4,500 RMB with food and accommodation included, or 5,000 RMB without.

Equipment Usage and Work Conditions

Li's first CAT 306E has been in use for about a year and has logged 1,100 to 1,200 working hours. The primary tasks have been municipal construction, including high and low voltage pipeline installation, water supply and gas pipeline digging, and landscaping. The jobs are typically short-term, with most lasting only 2 to 3 days.

In the Langfang area, the average work rates for 60 or 70 mini-excavators are as follows: - Hourly: 90–100 RMB

- Half-day: 500–600 RMB

- Full-day: 800 RMB

Work Efficiency and Fuel Consumption

Li is satisfied with the work efficiency of the CAT 306E. The digging speed is fast, the movements are smooth, and the joystick sensitivity is high, allowing for precise control. Li has received positive feedback from workers on his construction sites, who also praise the machine's speed.

As for fuel consumption, Li noted that the CAT 306E consumes around 200 RMB per workday, which is relatively high. However, the machine’s engine has a 43 kW power output, and Li accepts the fuel consumption as a trade-off for the performance it offers.

Li has used various types of diesel, including those from Sinopec, PetroChina, and local fuel trucks, with no issues regarding engine performance.

Product Performance and Issues

- Engine:

Li mentioned that the engine is relatively noisy, sometimes making it sound like the throttle is open more than it is, even when set to just 2–3 notches. After several hundred hours of use, the throttle motor developed a fault, but the dealer replaced it free of charge under warranty.

- Hydraulic System:

The hydraulic system experienced a minor issue when a hose on the boom burst. Due to urgency, Li replaced it himself before the dealer could arrive. However, the dealer later provided a replacement hose for free as a spare.

- Work Equipment:

The machine’s work equipment, especially the arm, performs with strong power. Li shared that during winter, while working on a trench for pipeline installation in frozen ground, the CAT 306E handled the task without any significant effort.

- Other Issues:

Li found the walking pedals to be too narrow, making it uncomfortable to operate the machine, and he suggested that this design could be improved.

After-Sales Service and Maintenance

Li expressed satisfaction with the after-sales service, which, although there was a four-day wait for parts during the throttle motor replacement, is generally responsive. The local dealer, West, provides maintenance services that are part of the package, with the first three services free of charge. For future services, Li plans to do the maintenance himself after the warranty expires.

Li has not yet decided whether he will continue to use the dealer’s parts after the warranty period or switch to third-party parts for maintenance.

Conclusion

Li's experience with the CAT 306E has been positive, with the machine’s strong performance in municipal construction tasks and its reliable fuel consumption. Despite encountering minor issues such as the throttle motor and hydraulic hose, the manufacturer and dealer have responded promptly to resolve them. Li’s decision to purchase a second CAT 306E, based on his satisfaction with the first machine, shows the confidence he has in the equipment. His insights provide valuable information for those considering investing in mini-excavators, as user feedback is often the most reliable source of information.

|

|

|

|