| Welcome, Guest |

You have to register before you can post on our site.

|

| Online Users |

There are currently 682 online users.

» 0 Member(s) | 671 Guest(s)

Amazon, Bing, Claude, DotBot, Facebook, Google, OpenAI, Petalbot, Semrush, Seznam, Trendiction

|

|

|

| JGM860E: JinGong’s New Energy Electric Loader – A Green and Intelligent Pioneer |

|

Posted by: MikePhua - 07-02-2025, 09:00 PM - Forum: Equipment Market News

- No Replies

|

|

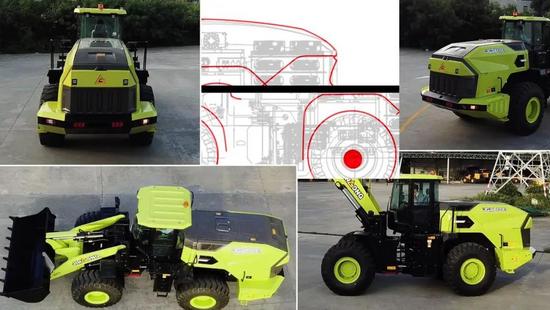

The "three-fold" design trend has recently swept across the tech world, capturing attention with its unique folding form and exquisite craftsmanship. Similarly, in the field of construction machinery, a product has emerged with an equally distinctive design and outstanding performance – the JinGong New Energy Electric Loader JGM860E. With its innovative design concept and cutting-edge technology, the JGM860E has quickly become a star product in the industry.

Unique Design Concept, Breaking Traditional Boundaries

The design inspiration for the JGM860E comes from diamond cutting faces and the triangular shape within JinGong’s New Energy logo. By incorporating a unique triangular folding design, the JGM860E not only enhances structural strength but also creates a sense of stability, safety, and forward momentum. Unlike traditional loader designs, this innovative folding form gives the machine a dynamic and vibrant appearance while providing operators with a wider field of view, ensuring smoother and more efficient operation.

Aurora Green Color – A Perfect Blend of Environmental Consciousness and Style

The JGM860E features an Aurora Green color scheme, resembling the flowing and mysterious beauty of the northern lights. This striking color not only captivates the eye, giving the loader a premium appearance, but also symbolizes JinGong’s commitment to green and environmental sustainability. Through this design, the JGM860E vividly reflects the construction machinery industry’s move toward a sustainable future, merging eco-friendly practices with intelligent technology.

Advanced Technology – Balancing Intelligence and Energy Efficiency

In terms of technology and functionality, the JGM860E excels. JinGong has customized a dedicated LVCU (Loader Variable Control Unit) for the loader, combined with a variable displacement hydraulic pump technology that significantly enhances the machine's endurance and energy efficiency. This means that whether operating in mining, ports, or other complex environments, the JGM860E can intelligently adjust its control strategy based on the specific needs of the task, achieving optimal performance, energy consumption, and safety.

An Industry Leader, Paving the Way for a Green Future

As a pioneer in the industry, the JGM860E, with its innovative diamond-cut design, unique Aurora Green color, and exceptional technical performance, has earned widespread recognition in the market. It is not just an ordinary electric loader; it represents a key step in the construction machinery industry’s journey toward a greener, smarter, and more efficient future. With the promotion of the JGM860E, JinGong New Energy is leading the way toward a more sustainable, intelligent future for the industry.

Conclusion

No matter from which angle you view it, the JGM860E stands as a capable and reliable partner in the field. Through the innovative design and advanced technology of the JGM860E, JinGong New Energy is showcasing breakthroughs in both green environmental practices and intelligent technology. As this product continues to be adopted, the future of the construction machinery industry will undoubtedly place more emphasis on combining environmental friendliness with high performance, driving the industry toward a greener and smarter era.

|

|

|

| "Terror" Chinese Excavator: User Insights and Experiences |

|

Posted by: MikePhua - 07-02-2025, 06:51 PM - Forum: Operator Talking

- No Replies

|

|

The "Terror" Chinese excavator, a nickname some users have given to certain Chinese-made excavators, has generated a variety of opinions and discussions. While Chinese excavators have gained recognition for their affordability and impressive features, the "Terror" moniker reflects a range of experiences—both positive and negative. This article delves into the user feedback, both from those who have had positive experiences and those who have encountered issues with these machines.

Overview of the "Terror" Chinese Excavator

The term "Terror" has been used informally by users to describe a Chinese-made excavator that may have garnered a reputation for less-than-ideal performance, at least in the eyes of some owners. Chinese excavators, as a category, are known for their affordability and the ability to get work done in a variety of settings, but this particular model seems to have sparked more controversy than others.

These excavators are typically used for small to medium-sized projects, ranging from residential landscaping to light construction tasks. They are often sold at a fraction of the price of Western brands, making them appealing for budget-conscious buyers.

Key Features and Appeal

Despite the mixed feedback, many users are attracted to the "Terror" excavator for its key features:

- Affordable Price: One of the primary reasons users opt for Chinese-made excavators is the significantly lower cost compared to established Western brands. For small contractors or those just starting out, the price makes it accessible without the financial commitment of a more expensive brand.

- Decent Performance for the Price: Many users report that the "Terror" performs adequately for smaller tasks, such as digging, trenching, and light landscaping. It’s capable of handling everyday tasks that don’t require the heavy-duty performance of more expensive models.

- Variety of Attachments: Like other excavators in its class, the "Terror" can be outfitted with a variety of attachments. This increases its versatility, making it useful for a range of applications from digging and lifting to material handling and grading.

Challenges and Issues with the "Terror" Excavator

While there are benefits to owning the "Terror" Chinese excavator, many users have shared concerns that lead to mixed reviews. Some of the most common issues include:

- Durability Concerns: A recurring theme in user feedback is concerns about the durability of the machine. Several users have noted that the build quality may not match the standards of more reputable brands. This has led to premature wear and tear, especially with the hydraulic system and undercarriage components.

- Hydraulic System Problems: The hydraulic system, which is crucial for an excavator’s operation, has been a point of contention for many owners. Users have reported issues with the hydraulics being underpowered or failing prematurely, which is a significant problem given how critical this system is to the machine’s functionality.

- Parts Availability: Another issue that has been frequently mentioned is the difficulty in obtaining replacement parts. Unlike well-established brands, Chinese excavators often lack a widespread service network or readily available spare parts, which can lead to long downtime for repairs.

- Poor Customer Service: Several users have reported poor customer service experiences with the manufacturers or distributors of the "Terror" excavator. Delays in support, lack of technical assistance, and difficulty finding authorized service centers have all contributed to user frustration.

- Mechanical Failures: Some owners have experienced frequent mechanical failures, ranging from engine problems to structural issues. These failures often result in unexpected downtime and additional repair costs, which can negate the initial cost savings of purchasing the machine.

User Experiences and Recommendations

Despite these challenges, many users continue to use and appreciate the "Terror" Chinese excavator for specific tasks, especially when they are working with a limited budget. Here are some common user experiences and tips for others considering the machine:- Budget-Friendly Option for Small Jobs: For users working on smaller residential or light commercial jobs, the "Terror" can be a decent option if you’re looking for a budget-friendly solution. As long as you are aware of the potential for mechanical issues and factor in the cost of repairs, it can still be a functional tool for basic tasks.

- Consideration of Maintenance and Repairs: If you’re considering purchasing a Chinese excavator like the "Terror," it’s important to budget for potential maintenance and repairs. Make sure you have a reliable local mechanic who is familiar with Chinese equipment, as this will help reduce downtime.

- Supplementing with Additional Equipment: Some users recommend supplementing the "Terror" excavator with additional equipment or attachments that can help offset any performance limitations. For example, using higher-quality hydraulic attachments can improve the machine’s overall performance.

- Know Your Limitations: It’s essential to understand that while the "Terror" may be sufficient for lighter work, it might not hold up to the same rigorous demands as more premium excavators. Be mindful of the machine's limitations and plan your projects accordingly to avoid pushing it too hard.

Conclusion

The "Terror" Chinese excavator embodies the duality that many Chinese-made construction machines face in the market—affordable and capable but often plagued with concerns regarding durability, performance, and service. While the price makes it an attractive option for those with budget constraints, the potential for mechanical issues and limited support can make ownership challenging. However, for users who understand these risks and are prepared for maintenance, the "Terror" can still be a useful machine for small-scale projects.

Ultimately, the decision to purchase a Chinese excavator like the "Terror" comes down to balancing the benefits of a low-cost solution with the possible frustrations that might arise from owning a less established brand.

|

|

|

| 2025 Rippa R-18Pro Mini Excavator: Key Features and Insights |

|

Posted by: MikePhua - 07-02-2025, 06:50 PM - Forum: Operator Talking

- No Replies

|

|

The 2025 Rippa R-18Pro mini excavator is a compact yet powerful machine designed to provide versatility and performance for a variety of tasks, particularly in smaller construction and landscaping projects. As mini excavators gain popularity for their ability to operate in tight spaces, the Rippa R-18Pro stands out for its combination of performance, ease of use, and affordability. This article explores the key features, advantages, and user feedback of the Rippa R-18Pro.

Overview of the 2025 Rippa R-18Pro

The Rippa R-18Pro is a modern, compact excavator designed to handle a range of applications, from trenching and digging to lifting and material handling. Its small size makes it an ideal choice for tight urban or residential job sites, where space is often limited.

Key specifications of the Rippa R-18Pro include: - Operating Weight: The R-18Pro weighs approximately 1.8 tons, making it a true mini excavator that is easy to transport and maneuver.

- Engine Power: The machine is powered by a 18.5 HP engine, providing enough horsepower to perform typical mini excavator tasks with ease.

- Hydraulic System: The R-18Pro boasts a strong hydraulic system that supports efficient digging and lifting, even in tough conditions.

- Digging Depth and Reach: With a digging depth of up to 2.5 meters and a reach of over 4 meters, the R-18Pro is capable of handling various jobs without the need for larger, more expensive machines.

- Tracks: The R-18Pro is equipped with rubber tracks, which provide both stability and low ground pressure, making it well-suited for use on sensitive surfaces like lawns and driveways.

Key Features and Benefits

- Compact Size and High Mobility: One of the standout features of the Rippa R-18Pro is its compact size, allowing it to work in tight spaces where larger equipment might struggle. Its narrow width and short tail swing make it an excellent choice for urban environments or areas with limited space.

- Ease of Operation: Many users have reported that the R-18Pro is easy to operate, even for those with minimal experience with mini excavators. The intuitive controls, combined with its responsive hydraulics, make it a user-friendly machine for various tasks.

- Affordable Price Point: The Rippa R-18Pro offers an attractive price point compared to many larger brands, making it a cost-effective choice for small businesses or individuals who need a reliable excavator without breaking the bank.

- Versatile Attachment Options: The machine is compatible with a variety of attachments, such as buckets, augers, and hydraulic breakers, which enhance its versatility for different jobs. This makes the R-18Pro suitable for tasks beyond traditional digging, such as landscaping, demolition, and light construction work.

- Durability and Reliability: Despite its compact size, the Rippa R-18Pro is built to last. Users have noted that it performs well even in demanding environments and holds up under regular use. Its simple design also means that there are fewer components that could wear out or malfunction.

- User Comfort: The operator’s cabin is designed for comfort, with easy access to controls and a spacious layout. The controls are ergonomic and allow for precise movements, reducing operator fatigue during long workdays.

User Feedback and Critiques

While the Rippa R-18Pro has received generally positive reviews, some users have pointed out areas for improvement:- Hydraulic Performance: A few users have mentioned that the hydraulic system can struggle with heavier loads, especially when digging in very tough soil or moving large rocks. However, this is generally expected for mini excavators in this class, and many find the performance adequate for lighter tasks.

- Attachment Compatibility: While the R-18Pro is compatible with many attachments, a few users have reported challenges in finding specialized attachments that fit perfectly. This may be due to the machine's relatively new presence in the market, and as the brand grows, it’s likely that more compatible attachments will become available.

- Maintenance and Service: Some users have raised concerns about the availability of spare parts and the need for timely servicing. As Rippa is still establishing itself in the global market, users in certain regions might face delays in obtaining parts or finding service providers. Ensuring a reliable service network could help alleviate this issue.

- Noise Level: A few operators have noted that the Rippa R-18Pro tends to be noisier than other mini excavators in its class. While this is not a major issue for most users, it might be a consideration for those working in noise-sensitive areas.

Conclusion

The 2025 Rippa R-18Pro mini excavator offers a solid balance of performance, compact size, and affordability, making it an excellent choice for small businesses, contractors, or homeowners who need a versatile, reliable machine for light to medium-duty tasks. Its small footprint allows it to work in confined spaces, while its powerful hydraulic system and range of attachments enhance its capabilities for a variety of applications.

While there are some areas where the machine could improve, particularly in hydraulic performance under heavy loads and attachment compatibility, the Rippa R-18Pro stands out as a cost-effective, easy-to-operate excavator for those on a budget. With its growing reputation and expanding market presence, it’s likely that future models will continue to refine and enhance these features, making it an even more compelling option for users seeking a mini excavator.

|

|

|

| 5x10 Dump Trailer for 2T Mini Excavator: Key Insights and Recommendations |

|

Posted by: MikePhua - 07-02-2025, 06:49 PM - Forum: Operator Talking

- No Replies

|

|

Dump trailers are invaluable tools for mini excavator owners, providing a practical solution for transporting and dumping materials like soil, gravel, or debris. A 5x10 dump trailer, in particular, is a popular choice for those with 2-ton mini excavators, as it offers a balance of size, capacity, and maneuverability. This article discusses the features, benefits, and considerations when selecting a 5x10 dump trailer to pair with a 2-ton mini excavator.

Why Choose a 5x10 Dump Trailer for a 2-Ton Mini Excavator?

A 5x10 dump trailer is an ideal size for a 2-ton mini excavator, offering ample space for materials while still being compact enough to easily maneuver in confined job sites. When paired with a mini excavator, it enhances productivity by providing a mobile and efficient way to transport materials to and from the work site. Here are a few reasons why this size trailer is a popular choice: - Optimal Size for Transporting Materials: A 5x10 trailer provides sufficient space to carry loads without being too large or cumbersome. This size allows for efficient loading and unloading, especially for smaller construction or landscaping projects.

- Maneuverability: A 2-ton mini excavator typically works in tighter spaces, such as residential properties or small commercial sites. The compact size of a 5x10 dump trailer complements the agility of a mini excavator, making it easier to navigate narrow paths and confined spaces.

- Balanced Load Capacity: A 5x10 dump trailer can comfortably carry around 3-5 tons of material, depending on the trailer's design and build quality. For a 2-ton mini excavator, this provides a practical weight capacity for transporting materials while ensuring that the load is manageable and safe.

Key Features to Look for in a 5x10 Dump Trailer

When shopping for a 5x10 dump trailer to pair with a 2-ton mini excavator, there are several important features to consider to ensure the trailer meets your needs. Here are the top aspects to look for:

- Load Capacity: The trailer should be rated for at least 3-5 tons of material. Ensure the trailer can handle the weight of the materials you’ll be transporting regularly. It’s also important to check the weight distribution to avoid overloading the trailer and causing damage to the mini excavator or the trailer itself.

- Tandem Axles vs. Single Axle: Most 5x10 dump trailers come with either a single or tandem axle configuration. Tandem axles are typically better for heavier loads, as they provide better stability and weight distribution. Single-axle trailers, on the other hand, are easier to maneuver and generally cost less but may not handle larger loads as well.

- Hydraulic Dumping Mechanism: A key feature of any dump trailer is the ability to unload quickly and efficiently. Look for a trailer with a hydraulic dumping system, as this makes the unloading process fast and easy. Some trailers may even have remote control systems that allow you to dump the load from a distance.

- Durable Construction: Ensure the trailer is made from high-quality materials such as steel or aluminum. Steel trailers tend to be more durable and are better suited for heavy-duty work, while aluminum trailers are lighter and more rust-resistant. For those who plan on using the trailer for construction work, a steel frame is generally recommended.

- Easy Loading and Unloading: A good 5x10 dump trailer should have low sides or a smooth ramp for easy loading and unloading. This is particularly important when using a mini excavator, as it can easily load materials onto the trailer without struggling with high sides or complicated ramps.

- Safety Features: Look for trailers equipped with safety features such as brakes, reflective tape, and LED lights for better visibility. Proper braking systems, especially if you’re towing heavy loads, are essential for safety on the road.

User Experiences and Recommendations

Many mini excavator owners who have used a 5x10 dump trailer appreciate the convenience it provides in terms of material handling. The combination of a 2-ton mini excavator and a 5x10 dump trailer creates an efficient system for small to medium-sized construction or landscaping jobs. Here are some common user experiences and recommendations:- Easy Maneuvering: Users report that the 5x10 size is perfect for maneuvering through tight spaces, such as between houses or around obstacles on construction sites. The compact design of both the mini excavator and the dump trailer makes it much easier to work in confined areas, compared to larger equipment.

- Perfect Pairing for Small Jobs: Many users find the 5x10 dump trailer to be a great size for small residential or commercial jobs. The capacity is enough for most landscaping and excavation tasks, and it’s easy to load and unload materials with a mini excavator.

- Improved Efficiency: When paired with a mini excavator, the dump trailer greatly improves overall efficiency. It reduces the need for multiple trips to dispose of waste or collect materials, saving time and fuel costs. Additionally, the hydraulic dumping feature speeds up the unloading process, allowing operators to focus on the next task quickly.

- Durability and Longevity: Several users have mentioned that their 5x10 dump trailers have held up well under regular use, especially those made from steel. Regular maintenance, such as checking the hydraulic system and ensuring the trailer is properly lubricated, is key to extending the trailer's lifespan.

Considerations for Choosing a Dump Trailer

While a 5x10 dump trailer is a great option for many, it’s important to carefully evaluate your specific needs before purchasing. Consider factors such as:- Frequency of Use: If you plan to use the trailer frequently for heavy loads or long distances, ensure it has the appropriate load capacity and construction quality to handle that workload.

- Towing Vehicle Compatibility: Check that your towing vehicle is compatible with the dump trailer. The trailer’s weight, along with the load it will carry, should not exceed the towing capacity of your vehicle.

- Budget: Prices for 5x10 dump trailers can vary significantly depending on the brand, materials, and features. It’s important to balance your budget with the trailer’s features and capabilities to ensure you’re getting the best value.

Conclusion

A 5x10 dump trailer is a great complement to a 2-ton mini excavator, offering both practicality and efficiency for small to medium-sized construction and landscaping jobs. With features like hydraulic dumping mechanisms, durable construction, and maneuverability, it provides an excellent solution for material transport and disposal. When choosing a trailer, ensure that it has the appropriate load capacity, construction quality, and safety features to meet your needs. A well-chosen 5x10 dump trailer can significantly improve your workflow and productivity on the job site.

|

|

|

| AGROTK Excavators: User Opinions, Comments, and Critiques |

|

Posted by: MikePhua - 07-02-2025, 06:47 PM - Forum: Operator Talking

- No Replies

|

|

AGROTK excavators are relatively new to the market, offering a range of mini and compact excavators designed for various industries. These machines have garnered attention due to their affordability and versatility, making them an attractive option for small businesses, contractors, and even personal use. However, as with any product, there are both positive and negative experiences shared by users. This article summarizes the feedback and critiques from owners and operators of AGROTK excavators.

Overview of AGROTK Excavators

AGROTK excavators are designed to offer reliable performance at a competitive price point, particularly in the mini-excavator and compact excavator categories. These machines are typically smaller, lightweight, and equipped with powerful hydraulic systems, making them suitable for a variety of applications such as landscaping, digging, and light construction.

Key features of AGROTK excavators include: - Compact design: Ideal for working in tight spaces, such as residential areas or small commercial sites.

- Affordable pricing: AGROTK aims to offer competitive prices compared to established brands.

- Versatility: Suitable for a wide range of tasks, from digging and trenching to lifting and grading.

- User-friendly controls: Designed for ease of operation, even for those with limited experience with heavy machinery.

User Feedback: Positive Experiences

Many users appreciate the affordability of AGROTK excavators, as they offer a lower initial cost compared to more well-known brands like Caterpillar or Kubota. For small businesses or individuals working on smaller projects, this cost savings can be a significant advantage. Some of the positive comments include:

- Value for Money: Many owners find that AGROTK excavators provide a good balance between price and performance. For individuals or companies that need an affordable machine for light to moderate work, AGROTK offers a solid option.

- Ease of Use: Operators who are new to excavators have found AGROTK machines to be easy to use, with intuitive controls and a straightforward setup. The simplicity of operation makes them suitable for a variety of users, including those without extensive heavy equipment experience.

- Compact Size and Maneuverability: The compact design of AGROTK excavators allows them to work in small spaces, making them especially popular for landscaping, utility work, and residential construction projects. Their maneuverability is a key selling point, as they can easily navigate tight corners and confined job sites.

- Good Hydraulics: Some users have praised the hydraulic system of AGROTK excavators, noting that they perform well for digging and lifting tasks. The hydraulic power is sufficient for most small to medium-sized jobs, contributing to effective performance on construction sites.

- Durability for the Price: While some users report that AGROTK excavators are not as rugged as higher-end brands, many still find them durable for the price. With proper maintenance, these machines can handle typical construction and landscaping tasks without issues.

User Critiques: Areas for Improvement

While AGROTK excavators offer good value for the price, several users have highlighted areas where the machines could improve. These critiques mainly focus on long-term durability, customer support, and certain design features. Some of the common negative feedback includes:

- Build Quality and Longevity: A few users have mentioned that the build quality of AGROTK excavators may not be on par with more established brands. Some parts, particularly the undercarriage and hydraulics, may wear out faster under heavy use. These issues can become a concern for those who plan to use the excavators for more demanding or high-frequency tasks.

- Limited Dealer Network: Another common critique is the limited dealer network for AGROTK excavators. Some users report difficulty in finding service centers or parts, which can be frustrating when maintenance or repairs are needed. A more widespread network of dealers and service centers could help improve the overall ownership experience.

- Hydraulic Performance on Larger Tasks: While the hydraulic system is generally well-regarded for smaller jobs, some users note that the machine's hydraulic performance can be lacking when dealing with more demanding tasks. This can be especially noticeable when working with tougher materials or larger workloads, where the excavator may struggle to maintain optimal performance.

- Fit and Finish: Some owners have commented on the overall fit and finish of the machine. While the design is functional, there have been reports of components that do not align perfectly, or small issues with assembly that may require attention soon after purchase. These may not be deal-breakers but could be frustrating for users who expect flawless construction.

- Customer Support and Warranty: Several users have expressed frustration with AGROTK's customer support. Some have had trouble getting timely responses from the manufacturer, and others have had difficulty accessing parts or getting warranty coverage. Effective customer service is crucial for long-term satisfaction, and improvements in this area could help boost user confidence.

Conclusion

AGROTK excavators are an attractive option for those looking for an affordable, compact machine for light to moderate tasks. Many users appreciate the value for money, ease of use, and maneuverability, especially for small businesses or individuals working on residential or landscaping projects. However, as with any product, there are areas where AGROTK could improve, particularly in terms of build quality, dealer support, and long-term durability.

For those who need a budget-friendly machine and are primarily focused on lighter work, AGROTK excavators can be a solid choice. However, prospective buyers should be aware of the potential downsides, particularly when it comes to customer service and the machine's performance on more demanding tasks.

|

|

|

| AGT Attachment Packages: A Comprehensive Overview |

|

Posted by: MikePhua - 07-02-2025, 06:46 PM - Forum: Equipment Parts , Attachments & Tools

- No Replies

|

|

AGT (Agricultural and General Technology) offers a variety of attachment packages designed to enhance the versatility and performance of mini-excavators and other machinery. These attachment packages allow operators to easily switch between different tools and implements, making it easier to tackle a wide range of tasks. Whether for construction, landscaping, or agricultural applications, the right attachment package can greatly improve efficiency and productivity.

What Are AGT Attachment Packages?

AGT attachment packages are specialized sets of tools and implements that can be fitted onto mini-excavators, tractors, or other machinery. These packages typically include a selection of attachments tailored to specific types of work, such as digging, grading, lifting, and material handling. They are designed to be quickly interchangeable, allowing operators to switch between tasks without needing separate machines or additional equipment.

AGT offers a range of attachment packages, each aimed at different industries and applications. Common types of attachments include: - Buckets: Used for digging, loading, and carrying materials. Sizes and designs vary depending on the type of work (e.g., trenching, grading, or material handling).

- Thumbs: Hydraulic or mechanical thumbs that allow operators to grip and handle materials, such as rocks, logs, or debris, with greater precision.

- Hydraulic Hammers: Ideal for breaking concrete, rock, or other hard surfaces, these hammers enhance productivity in demolition and excavation projects.

- Rippers and Graders: Used for breaking through tough soil or grading surfaces, often for land preparation, construction, or mining operations.

- Augers: For drilling holes, whether for fencing, planting, or geological work. Auger attachments come in various sizes to suit different types of tasks.

- Mulchers and Brush Cutters: These are designed for clearing vegetation, brush, and overgrowth in landscaping or land-clearing projects.

Benefits of AGT Attachment Packages

- Increased Versatility: By offering multiple attachments in one package, AGT allows operators to perform a wide range of tasks with a single machine. This makes it possible to tackle a variety of jobs without needing specialized equipment for each task.

- Cost-Effective: Instead of investing in multiple machines for different tasks, purchasing an AGT attachment package allows operators to save on equipment costs. This can be particularly beneficial for small businesses or contractors who need to maximize the utility of their machines.

- Time-Saving: With quick changeover between attachments, operators can reduce downtime between tasks, leading to faster project completion. The ease of switching attachments enhances efficiency, especially on busy job sites.

- Enhanced Productivity: The ability to switch between tasks without needing additional machinery allows for smoother operations and less setup time. This leads to increased productivity and reduced labor costs.

- Durability and Reliability: AGT attachments are designed to withstand tough conditions and heavy use. Whether working on construction sites or agricultural land, these attachments are built for durability and longevity.

Popular AGT Attachment Packages- Excavator Bucket Package: This package typically includes several bucket sizes designed for different types of digging and material handling tasks. Common attachments include trenching buckets, grading buckets, and heavy-duty buckets for moving large quantities of soil, gravel, or other materials.

- Landscaping Attachment Package: Designed for landscaping professionals, this package often includes a combination of augers, brush cutters, and grading blades. It’s ideal for tasks like tree planting, stump removal, and clearing brush and overgrowth.

- Construction and Demolition Package: This package may include hydraulic hammers, rippers, and heavy-duty buckets designed for breaking and digging through hard surfaces. These attachments are perfect for excavation, demolition, and land development.

- Agricultural Package: This package often includes specialized attachments for farming tasks, such as plows, rippers, and augers. These attachments are used for soil cultivation, planting, and other agricultural needs.

- Material Handling Package: Designed for moving heavy loads and materials, this package typically includes forks, clamps, and thumbs for lifting and securing various materials. It is useful for handling pallets, logs, or scrap material.

Considerations When Choosing an AGT Attachment Package- Machine Compatibility: Ensure that the attachment package is compatible with your mini-excavator or tractor. Some packages are designed specifically for certain models, so it’s essential to verify compatibility before purchase.

- Task Requirements: Consider the type of work you will be doing most frequently. If your tasks mostly involve digging and grading, an excavator bucket and grading blade package may be ideal. For landscaping, look for packages that include brush cutters and augers.

- Quality and Durability: The durability of the attachments is crucial, especially if you plan to use them on tough, demanding jobs. Look for packages that feature high-quality materials, reinforced components, and robust construction.

- Budget: AGT attachment packages can vary in price depending on the attachments included and the machine’s size compatibility. Be sure to evaluate the long-term savings and productivity benefits of investing in a package versus buying individual attachments.

User Experiences and Feedback

Many users who have purchased AGT attachment packages report that the ability to easily swap attachments has improved their workflow. For example, contractors working on construction or landscaping projects appreciate the versatility these packages offer, as they can quickly switch from grading to trenching or debris removal.

In addition, some operators have highlighted the cost savings associated with purchasing a package deal compared to buying each attachment separately. The convenience of having multiple tools in one set reduces the need for multiple machines, which helps businesses save on both initial investment and maintenance costs.

However, a few users have noted that while the attachments are generally well-built, it is essential to make sure the machine’s hydraulic system is capable of handling the increased load that some attachments may impose, such as hydraulic hammers or large buckets.

Conclusion

AGT attachment packages provide a flexible, cost-effective solution for a variety of industries, allowing operators to expand the capabilities of their mini-excavators and tractors. Whether you are in construction, landscaping, or agriculture, the right attachment package can boost efficiency, productivity, and profitability. When selecting a package, ensure compatibility with your machinery, consider the specific tasks you’ll be performing, and choose high-quality, durable attachments that will stand up to tough working conditions.

|

|

|

| Amulet HK01-3 PowerClamp Hydraulic Thumb with 9" Bucket on Small Mini-Excavator |

|

Posted by: MikePhua - 07-02-2025, 06:45 PM - Forum: Operator Talking

- No Replies

|

|

When it comes to enhancing the functionality of mini-excavators, attachments such as hydraulic thumbs are a popular choice among operators. The Amulet HK01-3 PowerClamp hydraulic thumb, when paired with a 9" bucket, can significantly improve the versatility and performance of smaller mini-excavators. This article explores the benefits, performance, and considerations of using the Amulet HK01-3 PowerClamp hydraulic thumb in combination with a small mini-excavator, based on user experiences and feedback.

What is the Amulet HK01-3 PowerClamp Hydraulic Thumb?

The Amulet HK01-3 PowerClamp hydraulic thumb is an attachment designed to be installed on mini-excavators, offering enhanced gripping capabilities. Unlike traditional mechanical thumbs, the hydraulic thumb operates through a hydraulic system that allows it to open and close independently of the bucket. This feature provides superior flexibility when handling a wide range of materials, from rocks and logs to scrap and debris.

The hydraulic thumb offers several advantages over mechanical thumbs, including: - More precise control: The hydraulic thumb allows operators to adjust the grip force and control how materials are held, making it easier to handle delicate or irregularly shaped objects.

- Increased versatility: With the ability to clamp down firmly on materials while digging or moving, the hydraulic thumb can assist with a variety of tasks, such as lifting, gripping, and sorting materials in tight spaces.

- Higher efficiency: Compared to manual mechanical thumbs, the hydraulic thumb is more efficient in demanding applications, providing a quick and reliable grip without requiring manual intervention.

Pairing the Amulet HK01-3 with a 9" Bucket

One of the unique aspects of the setup discussed here is the use of a 9" bucket alongside the Amulet HK01-3 hydraulic thumb. The smaller bucket size, combined with the hydraulic thumb, provides a compact solution for mini-excavators. This configuration is ideal for tasks that require precision and flexibility in confined areas, such as landscaping, small-scale demolition, and digging around utilities.

The 9" bucket is well-suited for mini-excavators because:- Better precision: The smaller bucket is ideal for detailed, precision digging in narrow or crowded spaces.

- Less strain on the machine: A 9" bucket typically places less strain on a mini-excavator's hydraulic system compared to larger buckets, making it easier for the machine to maintain power and efficiency while using the hydraulic thumb.

- Compactness: The smaller size allows for better maneuverability, which is an advantage in tight working conditions such as residential sites or urban areas.

Benefits of Using the Hydraulic Thumb with a 9" Bucket

The combination of the Amulet HK01-3 PowerClamp hydraulic thumb and a 9" bucket on a small mini-excavator offers several benefits:

- Improved Material Handling: The hydraulic thumb enhances the mini-excavator’s ability to pick up, move, and manipulate materials that might otherwise be difficult to handle. For example, operators can use the hydraulic thumb to grip rocks, logs, or debris with ease, improving productivity and reducing manual labor.

- Increased Versatility: With this attachment, operators can use the mini-excavator for a variety of tasks, from grading and digging to lifting and material sorting. The hydraulic thumb provides a higher level of flexibility in tasks where a standard bucket may not be enough.

- Compact Power: Despite being paired with a 9" bucket, the setup doesn’t sacrifice power. The hydraulic thumb can be easily integrated with the mini-excavator’s existing hydraulic system, allowing for enhanced performance without additional machinery.

- Better Control in Tight Spaces: The small size of the 9" bucket and the precise action of the hydraulic thumb make this setup particularly beneficial for jobs in tight, confined spaces. Operators can work around obstacles and maneuver with ease, improving efficiency in challenging environments.

Challenges and Considerations

While the Amulet HK01-3 PowerClamp hydraulic thumb offers numerous benefits, there are some considerations to keep in mind:- Hydraulic Compatibility: Before installing the hydraulic thumb, ensure that your mini-excavator's hydraulic system is compatible with the attachment. Some mini-excavators may require modifications to accommodate the hydraulic thumb, and ensuring compatibility is crucial for optimal performance.

- Weight and Balance: Adding a hydraulic thumb to a small mini-excavator may slightly affect the balance of the machine. Operators should take care when using the attachment to ensure that the excavator remains stable during operations, especially when handling large or heavy materials.

- Maintenance: Like any hydraulic system, the PowerClamp hydraulic thumb requires regular maintenance to ensure proper functioning. This includes checking hydraulic fluid levels, inspecting hoses for leaks, and ensuring that the thumb operates smoothly without excessive wear.

- Cost: While the Amulet HK01-3 PowerClamp hydraulic thumb offers excellent functionality, it does come with an associated cost. Operators should consider the return on investment based on the frequency and type of tasks they intend to perform.

User Feedback

Many users who have tested the Amulet HK01-3 PowerClamp hydraulic thumb with a 9" bucket report that the setup significantly improves the capabilities of their mini-excavators. The precision and control offered by the hydraulic thumb make it a great addition for tasks that involve handling a variety of materials in confined spaces.

Some operators note that the combination is particularly useful for landscaping projects, small demolition tasks, and jobs that require precision digging. The 9" bucket provides excellent control, while the hydraulic thumb ensures that materials can be gripped and moved effectively.

However, a few users have mentioned the importance of ensuring the hydraulic system is properly set up to handle the thumb attachment. Any issues with hydraulic pressure or compatibility could affect the performance of the system.

Conclusion

The Amulet HK01-3 PowerClamp hydraulic thumb, when paired with a 9" bucket on a small mini-excavator, is a powerful combination for increasing the versatility and efficiency of your equipment. It allows operators to handle materials with greater precision and ease, making it an invaluable tool for a wide range of tasks. While there are some considerations related to installation, maintenance, and cost, the overall benefits of enhanced control, versatility, and productivity make this setup an excellent choice for many mini-excavator operators.

|

|

|

| Bobcat 324 Fuel Issue: Troubleshooting and Solutions |

|

Posted by: MikePhua - 07-02-2025, 06:37 PM - Forum: Excavator Repair Shop & Troubleshooting

- No Replies

|

|

The Bobcat 324 is a compact mini-excavator known for its performance and maneuverability in tight spaces. However, like any machinery, fuel system issues can arise, and many users have reported experiencing fuel supply problems, leading to difficulty starting the engine or unstable operation. In this article, we will explore common causes of fuel issues in the Bobcat 324, how to troubleshoot the problem, and possible solutions to get the machine running smoothly again.

1. Common Symptoms of Fuel Issues

Fuel-related problems in the Bobcat 324 are typically marked by symptoms such as difficulty starting, rough running, or power loss during operation. If you notice any of the following, it could indicate an issue with the fuel system: - Engine Difficulty Starting or Failing to Start: Insufficient fuel supply or blockages in the fuel system can make it difficult to start the engine.

- Loss of Engine Power: If the engine runs but the power output is lower than expected, it could be due to restricted fuel flow or a clogged fuel filter.

- Engine Stalling: Air entering the fuel system or a disruption in fuel supply can cause the engine to stall or shut off unexpectedly.

2. Common Causes of Fuel Problems

There are several reasons why fuel issues might occur in the Bobcat 324. Understanding these causes can help you identify the source of the problem and fix it efficiently:- Clogged Fuel Filter: The fuel filter is designed to capture impurities in the fuel before it reaches the engine. If the filter becomes clogged, fuel flow is restricted, which may lead to engine starting problems or poor performance.

- Fuel Pump Failure: The fuel pump is responsible for delivering fuel to the engine. If the fuel pump is damaged or malfunctioning, fuel may not be delivered properly, causing the engine to fail to start or run erratically.

- Air in the Fuel System: Air entering the fuel system can cause a variety of problems, including difficulty starting and stalling. This is usually a result of leaks or improper bleeding of the system.

- Poor Quality Fuel: Low-quality fuel, which may contain water, dirt, or other contaminants, can clog the fuel system and cause poor engine performance.

- Leaking Fuel Lines: If there are cracks or leaks in the fuel lines or connectors, fuel may not be delivered properly, leading to insufficient fuel supply and performance issues.

- Fuel Pressure Issues: If the fuel pressure is either too high or too low, it can cause problems with fuel delivery, leading to engine stalling or power loss.

3. Troubleshooting and Diagnostics

If you experience fuel issues with your Bobcat 324, it’s important to follow a systematic troubleshooting approach to pinpoint the cause of the problem:- Check Fuel Level: Start by checking the fuel tank to ensure that it has enough fuel. If the fuel level is low, fill it up and see if this resolves the issue.

- Inspect the Fuel Filter: Examine the fuel filter for any signs of clogging or dirt accumulation. If the filter is dirty or clogged, it should be replaced or cleaned.

- Inspect the Fuel Pump and Lines: Check the fuel pump and fuel lines for any signs of damage, leaks, or wear. If you notice any issues, repair or replace the affected components.

- Check Fuel Line Connections: Ensure that all fuel line connections are tight and there are no leaks. If any connections are loose, tighten them and check if this resolves the issue.

- Check for Air in the Fuel System: If air has entered the fuel system, you may need to bleed the system to remove the air and restore proper fuel flow. Ensure that the system is properly sealed to prevent further air intrusion.

- Test Fuel Quality: If you suspect the fuel is contaminated, drain the tank, clean the fuel system, and refill with fresh, high-quality fuel.

4. Solutions to Fix the Fuel Issue

Once you’ve identified the cause of the fuel issue, there are several solutions you can implement:- Replace the Fuel Filter: If the fuel filter is clogged or dirty, replace it with a new one. Use a high-quality filter that meets the manufacturer's specifications to ensure proper fuel flow.

- Replace or Repair the Fuel Pump: If the fuel pump is malfunctioning, it will need to be replaced. The fuel pump is a critical component, and its failure can lead to severe engine problems.

- Bleed the Fuel System and Seal Connections: If air is present in the fuel system, you’ll need to bleed it to remove the air pockets. Additionally, check all fuel line connections to ensure they are tight and properly sealed to prevent leaks.

- Clean the Fuel System: If poor-quality fuel is the issue, clean the fuel system thoroughly, replacing any contaminated components as necessary. Always use fresh, high-quality fuel to avoid future issues.

- Adjust Fuel Pressure: If the fuel pressure is outside the recommended range, adjust the fuel pump or pressure regulator to ensure the proper pressure for optimal engine performance.

5. Preventative Measures

To avoid fuel-related issues in the future, consider implementing the following preventative measures:- Regularly Replace the Fuel Filter: Regularly replace the fuel filter to ensure that impurities do not clog the system and restrict fuel flow.

- Use High-Quality Fuel: Always use high-quality fuel that meets the manufacturer’s specifications. Avoid using low-grade or contaminated fuel, as it can cause long-term damage to the system.

- Inspect the Fuel System Regularly: Periodically check the fuel system, including the pump, lines, and connections, to ensure there are no leaks or wear that could lead to fuel delivery issues.

- Perform Routine Maintenance: Regular maintenance is key to keeping the Bobcat 324 running smoothly. Perform routine checks on the fuel system, air filter, and other critical components to prevent issues before they arise.

6. Conclusion

Fuel problems in the Bobcat 324, while common, can be resolved effectively with proper troubleshooting and maintenance. By understanding the root causes of fuel issues and following a systematic diagnostic process, you can restore your mini-excavator to full performance. Regular maintenance and preventive measures are essential for ensuring the longevity of your machine and preventing future fuel-related problems. If the issue persists or is too complex to fix on your own, it may be worth consulting a professional technician for further assistance.

|

|

|

| Bobcat 418 E10 Expansion Tube Leak: Troubleshooting and Solutions |

|

Posted by: MikePhua - 07-02-2025, 06:36 PM - Forum: Excavator Repair Shop & Troubleshooting

- No Replies

|

|

The Bobcat 418 E10 mini-excavator is known for its compact size, reliability, and performance in tight spaces. However, as with any piece of machinery, occasional issues may arise, such as leaks. One common issue reported by owners is the leaking of the expansion tube, which can lead to fluid loss and potential performance problems if not addressed in a timely manner. In this article, we’ll explore the causes of expansion tube leaks in the Bobcat 418 E10, how to troubleshoot the problem, and the best solutions to fix it.

1. Understanding the Expansion Tube and Its Role

The expansion tube in the Bobcat 418 E10 is part of the hydraulic system, designed to handle the expansion and contraction of hydraulic fluid as it heats up and cools down during operation. Its main function is to provide a space for the fluid to expand, helping to maintain the correct pressure in the hydraulic system. If the expansion tube begins to leak, it can result in a drop in hydraulic fluid levels, leading to inefficient operation, increased wear on components, and potential hydraulic system failure.

2. Common Causes of Expansion Tube Leaks

Several factors can cause the expansion tube to leak, and identifying the root cause is the first step in resolving the issue. Here are some of the most common causes: - Aging or Wear: Over time, the expansion tube can degrade due to constant exposure to heat and pressure fluctuations. This natural wear and tear can cause cracks or holes in the tube, leading to fluid leakage.

- Improper Installation: If the expansion tube was not installed correctly during manufacturing or maintenance, it could be prone to leakage. A poorly fitted tube may cause seals to fail or become loose, allowing fluid to escape.

- Damage from Debris: During operation, small rocks, dirt, and other debris can sometimes get caught in the hydraulic system, damaging the expansion tube or its seals. This external damage can lead to leaks.

- High Pressure: If the hydraulic system operates at a higher pressure than it is designed for, it can strain the expansion tube and its seals. This excessive pressure can cause leaks or ruptures in the tube.

3. Troubleshooting the Leak

If you notice that your Bobcat 418 E10 is leaking fluid, especially around the expansion tube area, it’s important to follow a systematic troubleshooting process. Here’s how you can check for and diagnose an expansion tube leak:- Inspect the Area: Start by inspecting the area around the expansion tube for any visible signs of fluid leakage. Look for oil spots on the ground, fluid accumulation near the tube, or discoloration of nearby components. This will give you an indication of where the leak is coming from.

- Check the Expansion Tube Condition: Examine the expansion tube closely for cracks, holes, or signs of wear. If the tube appears to be damaged, it will likely need to be replaced.

- Verify the Hydraulic Fluid Level: Low hydraulic fluid levels can be a sign that there is a significant leak in the system. Check the hydraulic fluid level and top it off if necessary. If the fluid level continues to drop, it’s a strong indication of a leak in the system.

- Test the Hydraulic Pressure: If you have access to a hydraulic pressure gauge, check the pressure in the hydraulic system. If the pressure is too high, it could be causing stress on the expansion tube, leading to leaks.

4. Solutions for Fixing the Leak

Once you’ve identified the source of the leak, there are a few different solutions depending on the extent of the damage to the expansion tube:- Replace the Expansion Tube: If the expansion tube is cracked or damaged beyond repair, it will need to be replaced. Ensure you use a replacement tube that matches the specifications of the original. This will ensure proper function and prevent future leaks.

- Tighten or Reseat Connections: If the leak is due to loose connections or improperly seated seals, the fix may be as simple as tightening the connections or reseating the seals. This can help prevent fluid from escaping and restore the system’s integrity.

- Address Hydraulic System Pressure: If excessive pressure is the cause of the leak, consider adjusting the hydraulic pressure to within the manufacturer’s recommended limits. If necessary, consult a professional to properly calibrate the system.

- Clean the System: If debris is the culprit, it’s important to clean the hydraulic system thoroughly. Removing any dirt or particles that may have caused damage to the expansion tube will help prevent further issues. Regularly cleaning the hydraulic system can also prolong the life of components and reduce the likelihood of future leaks.

5. Preventative Measures

To avoid future expansion tube leaks and other hydraulic system issues, consider taking the following preventative measures:- Regular Maintenance: Ensure that the Bobcat 418 E10 undergoes regular maintenance, including hydraulic system checks, fluid changes, and visual inspections of key components like the expansion tube. Regular maintenance can catch small issues before they become major problems.

- Use Quality Fluid: Always use high-quality hydraulic fluid that meets the manufacturer’s specifications. Low-quality or incorrect fluid can cause damage to the system over time, leading to leaks and other failures.

- Protect the System from Debris: During operation, try to keep the hydraulic system free from dirt, rocks, and other debris that could cause damage. Using a protective cover or working in cleaner environments can help reduce the risk of debris-related issues.

- Monitor Pressure Levels: Regularly monitor the hydraulic pressure and ensure that it is within the recommended range. Excessive pressure can cause wear on components and lead to leaks.

6. Conclusion

Leaking expansion tubes in the Bobcat 418 E10 can be a frustrating issue, but with proper troubleshooting and maintenance, it can be resolved effectively. By understanding the causes of the leak, performing regular maintenance, and taking preventive measures, you can ensure the longevity and efficiency of your mini-excavator’s hydraulic system. If the problem persists or is too complex to address on your own, it may be worth consulting a professional technician to ensure the proper repair and optimal performance of the machine.

|

|

|

| Case CX36B Ownership: A Practical Review |

|

Posted by: MikePhua - 07-02-2025, 06:35 PM - Forum: Operator Talking

- No Replies

|

|

The Case CX36B is a compact excavator that has gained attention for its performance, reliability, and versatility. As with any piece of construction equipment, owning and operating the CX36B comes with both advantages and challenges. In this article, we will explore the ownership experience of the Case CX36B, covering its features, performance, maintenance considerations, and the pros and cons based on feedback from real-world owners.

1. Overview of the Case CX36B

The Case CX36B is a mini-excavator designed for operators who need a machine that can handle small to medium-sized jobs with precision and power. Weighing in at around 8,000 pounds, it is ideal for working in confined spaces such as residential areas, landscaping projects, and small construction sites. Despite its compact size, the CX36B offers impressive digging power and an efficient hydraulic system.

Some key features of the Case CX36B include: - Powerful Engine: The CX36B is powered by a reliable engine that delivers excellent performance for its size, ensuring that operators can handle tough tasks without compromising on fuel efficiency.

- Compact Design: Its compact design allows for better maneuverability in tight spaces, which is a huge advantage when working in residential or urban environments.

- User-Friendly Controls: The CX36B comes with intuitive controls that make it easy for both novice and experienced operators to operate the machine effectively.

- Hydraulic System: The hydraulic system provides smooth and powerful movements, making the machine ideal for tasks such as digging, lifting, and grading.

2. Performance and Capability

The Case CX36B has been praised for its ability to perform well in various tasks despite being classified as a mini-excavator. Its digging depth, lift capacity, and reach make it suitable for a wide range of applications:- Digging Depth: With a maximum digging depth of around 9 feet, the CX36B is capable of handling most tasks that require excavation at moderate depths.

- Lift Capacity: The lift capacity of the CX36B is more than sufficient for general tasks such as lifting dirt, rocks, and other construction materials.

- Reach: The machine's reach and breakout force are strong enough for tasks such as trenching, digging foundations, and performing landscaping work.

For most users, the CX36B provides the ideal balance between power and size. It can easily access hard-to-reach areas while still having the power to handle demanding jobs. The combination of compactness and strength makes it a popular choice for small-scale contractors and landscapers.

3. Maintenance and Reliability

One of the key factors to consider when owning an excavator like the Case CX36B is its maintenance and overall reliability. Many owners have reported that the CX36B is a reliable machine with relatively low maintenance needs. However, like all equipment, it requires regular care to ensure it remains in top working condition.

Here are a few maintenance considerations:- Regular Servicing: Regular servicing of the engine, hydraulic system, and other components is essential to avoid downtime and ensure the machine's longevity. This includes changing the engine oil, replacing filters, and inspecting the hydraulic fluid regularly.

- Track and Undercarriage Maintenance: As with many mini-excavators, the undercarriage and tracks need to be maintained. Regular cleaning and inspection of the tracks can help prevent wear and tear, which is particularly important in rough or rocky terrain.

- Hydraulic System Care: The hydraulic system should be monitored for leaks, pressure drops, and fluid contamination. Keeping the hydraulic system in good working order is critical for the performance of the excavator.

- Engine and Cooling System: Regularly checking the engine’s cooling system and ensuring it’s clean and functioning correctly can prevent overheating and extend the life of the engine.

While the CX36B generally performs well with minimal issues, owners should stay on top of routine maintenance to avoid costly repairs.

4. Pros of the Case CX36B

Based on user reviews and feedback, here are some of the standout advantages of owning the Case CX36B:- Compact and Maneuverable: The small size of the CX36B makes it perfect for working in confined spaces, such as residential yards or urban areas. It can fit through narrow gates and access areas that larger machines can’t.

- Fuel Efficiency: The CX36B offers excellent fuel efficiency for its class, which helps reduce operating costs over time. The engine’s performance ensures it delivers the right amount of power without excessive fuel consumption.

- Versatility: The machine is versatile enough to handle a wide variety of tasks, from digging and trenching to grading and lifting. Its ease of operation and wide range of attachments make it a great tool for various projects.

- Reliability: Many owners report that the CX36B is a highly reliable machine. With proper maintenance, it can last for many years, even in challenging working conditions.

- Comfort: The CX36B is designed with operator comfort in mind. The cab is spacious for its size, and the controls are ergonomically placed, reducing operator fatigue during long hours of work.

5. Cons of the Case CX36B

While the CX36B offers great value and performance, there are a few drawbacks that potential buyers should consider:- Limited Lift Capacity: While the CX36B performs well for most tasks, it has a limited lift capacity compared to larger excavators. For jobs that require lifting heavy materials, the machine may not be the best choice.

- Speed: Due to its compact size and design, the CX36B is slower than larger excavators, which could be a disadvantage for time-sensitive tasks that require rapid movement.

- Ground Clearance: Some users have noted that the CX36B’s ground clearance is not as high as that of other excavators, making it less suitable for rough terrain or heavy-duty applications.

- Attachments and Customization: While the CX36B supports various attachments, some users have found that the selection of compatible attachments is more limited compared to other brands.

6. Conclusion

The Case CX36B is a reliable and efficient mini-excavator that offers a great balance of power, maneuverability, and versatility. It’s an ideal choice for small to medium-sized contractors, landscapers, and anyone who needs a compact machine that can handle a variety of tasks in tight spaces.

With regular maintenance, the CX36B can provide many years of dependable service. While it may not be the best choice for heavy-duty lifting or extremely rough terrain, it excels in tasks such as digging, trenching, and grading. For those seeking an affordable, durable, and easy-to-operate excavator, the Case CX36B is certainly worth considering.

|

|

|

|